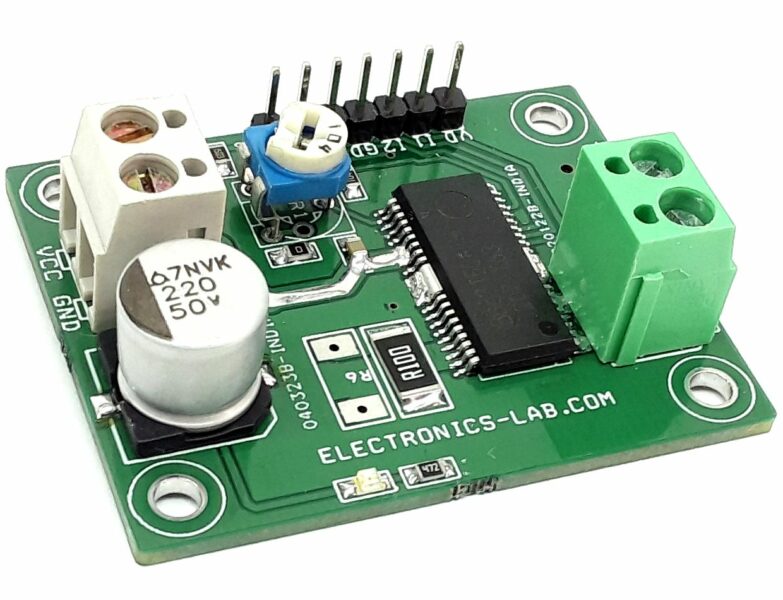

Closed Loop Analog Position Control using Brushed DC Motor and Potentiometer

- Rajkumar Sharma

- 1.246 Views

- easy

- Tested

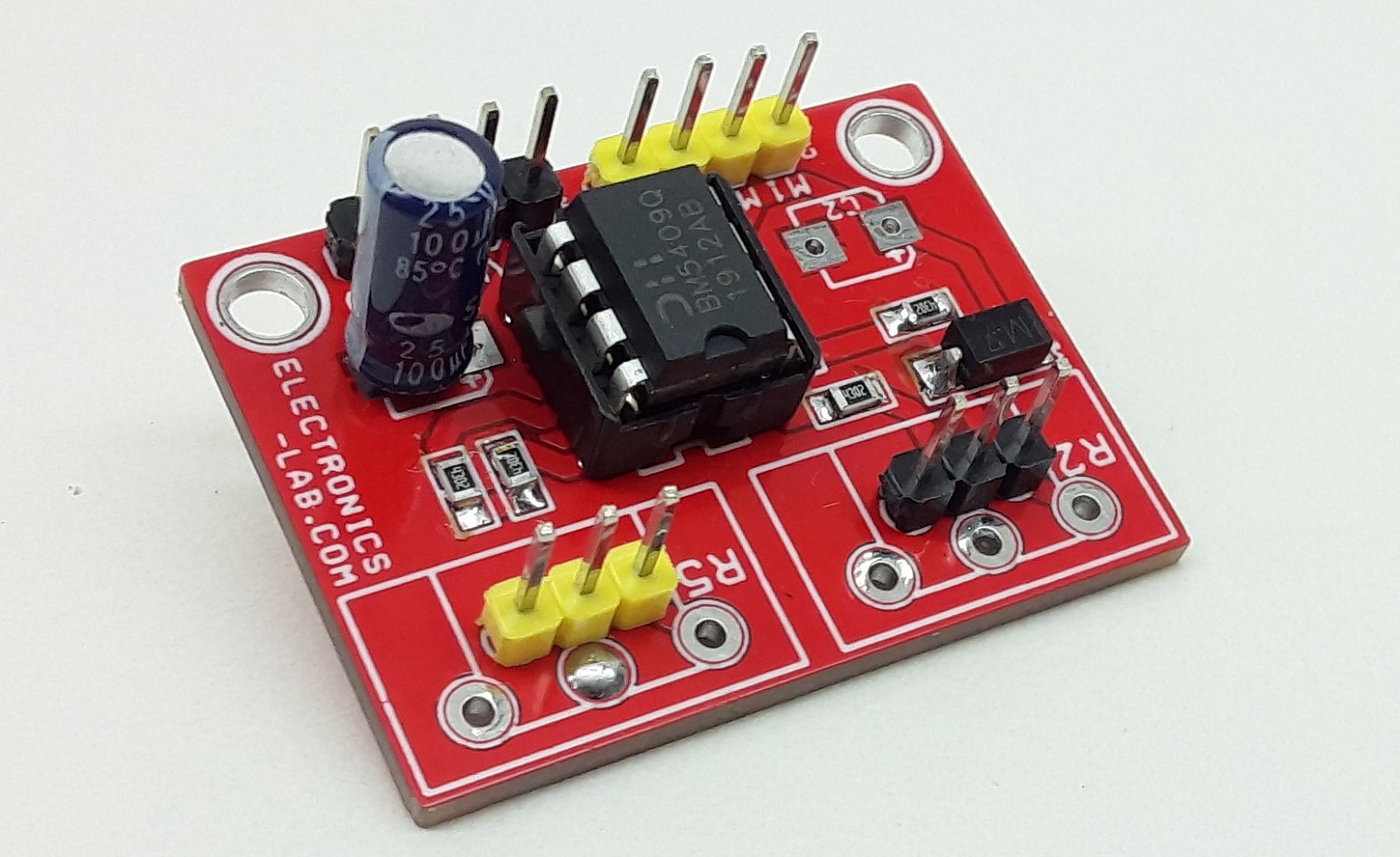

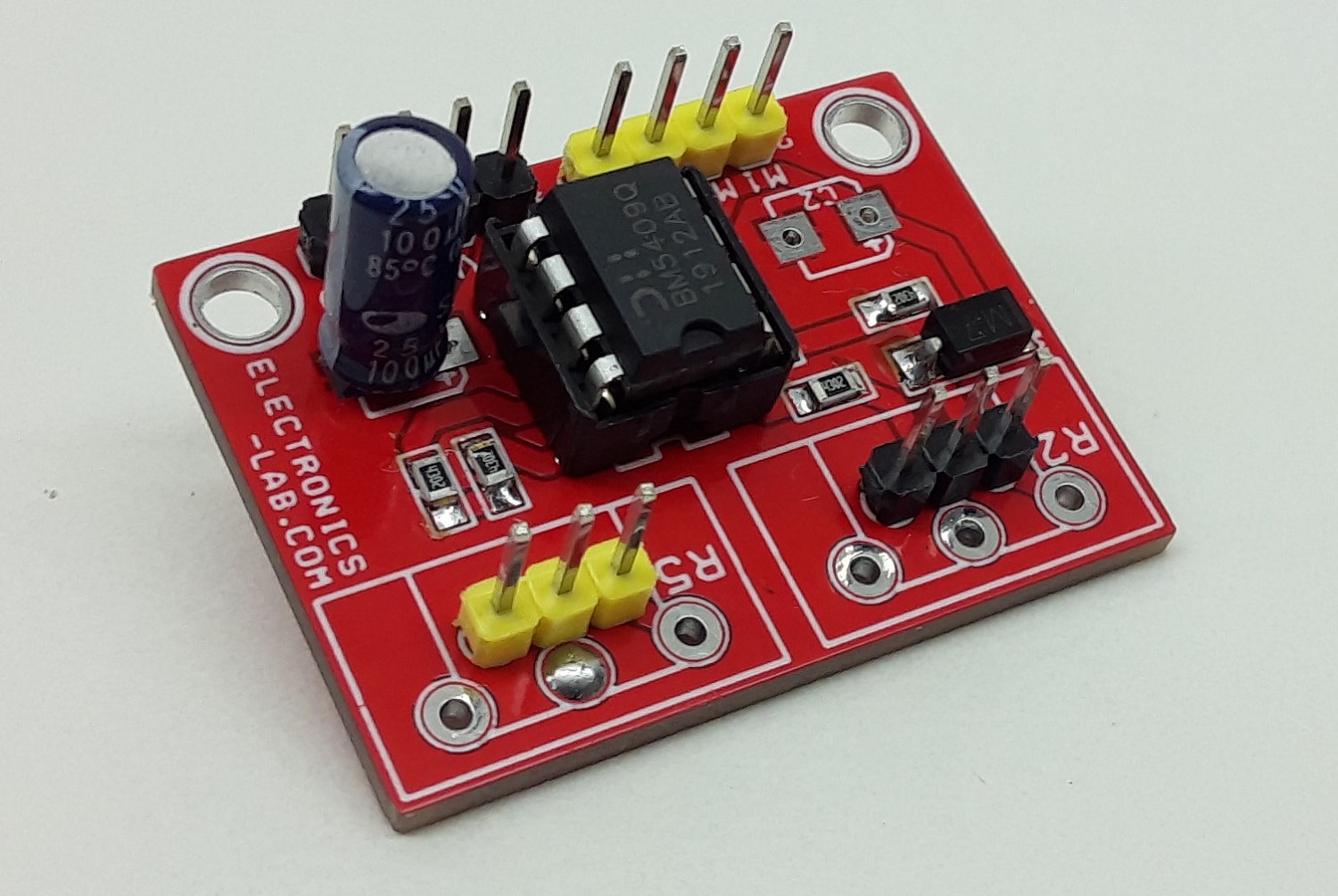

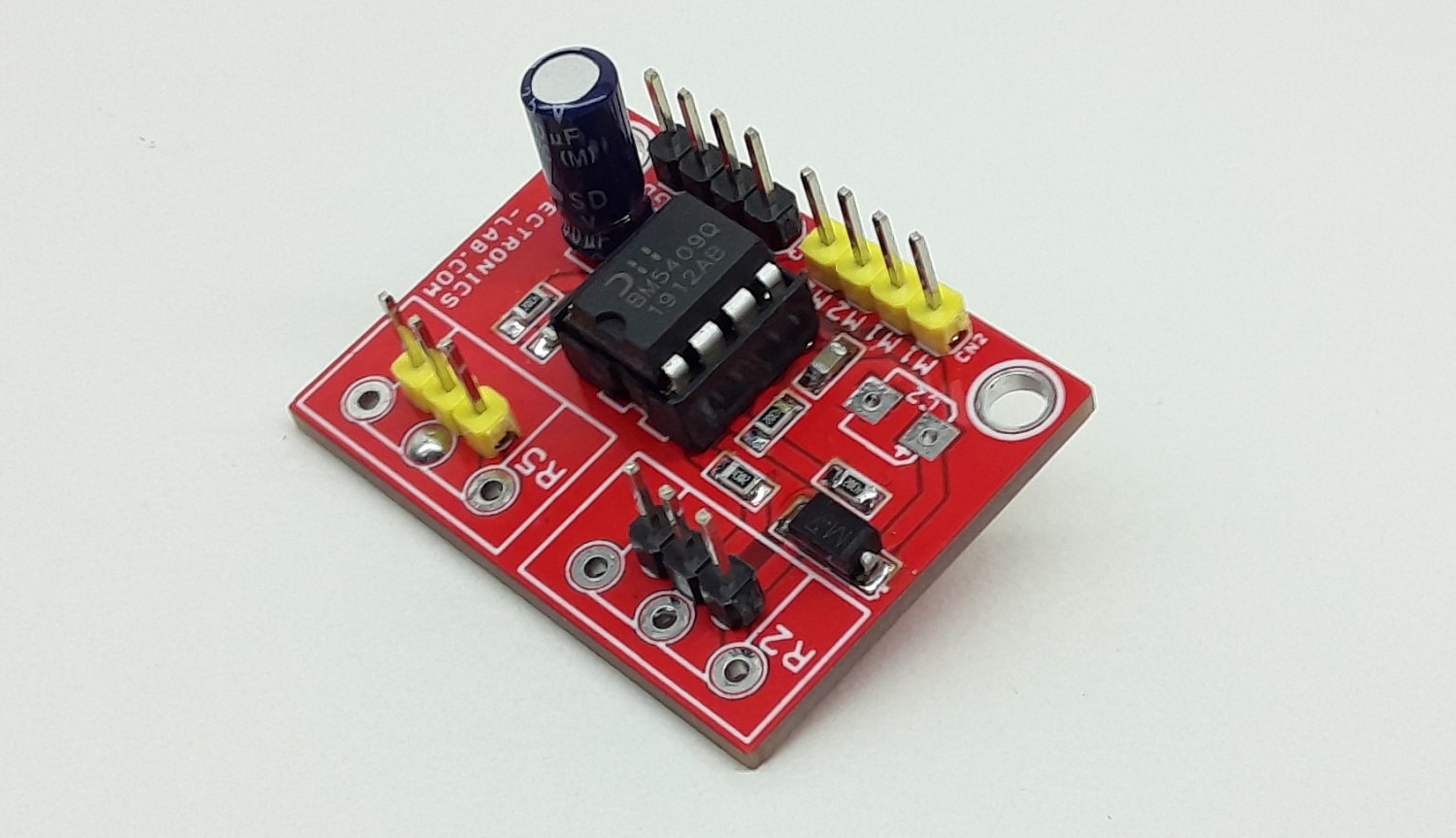

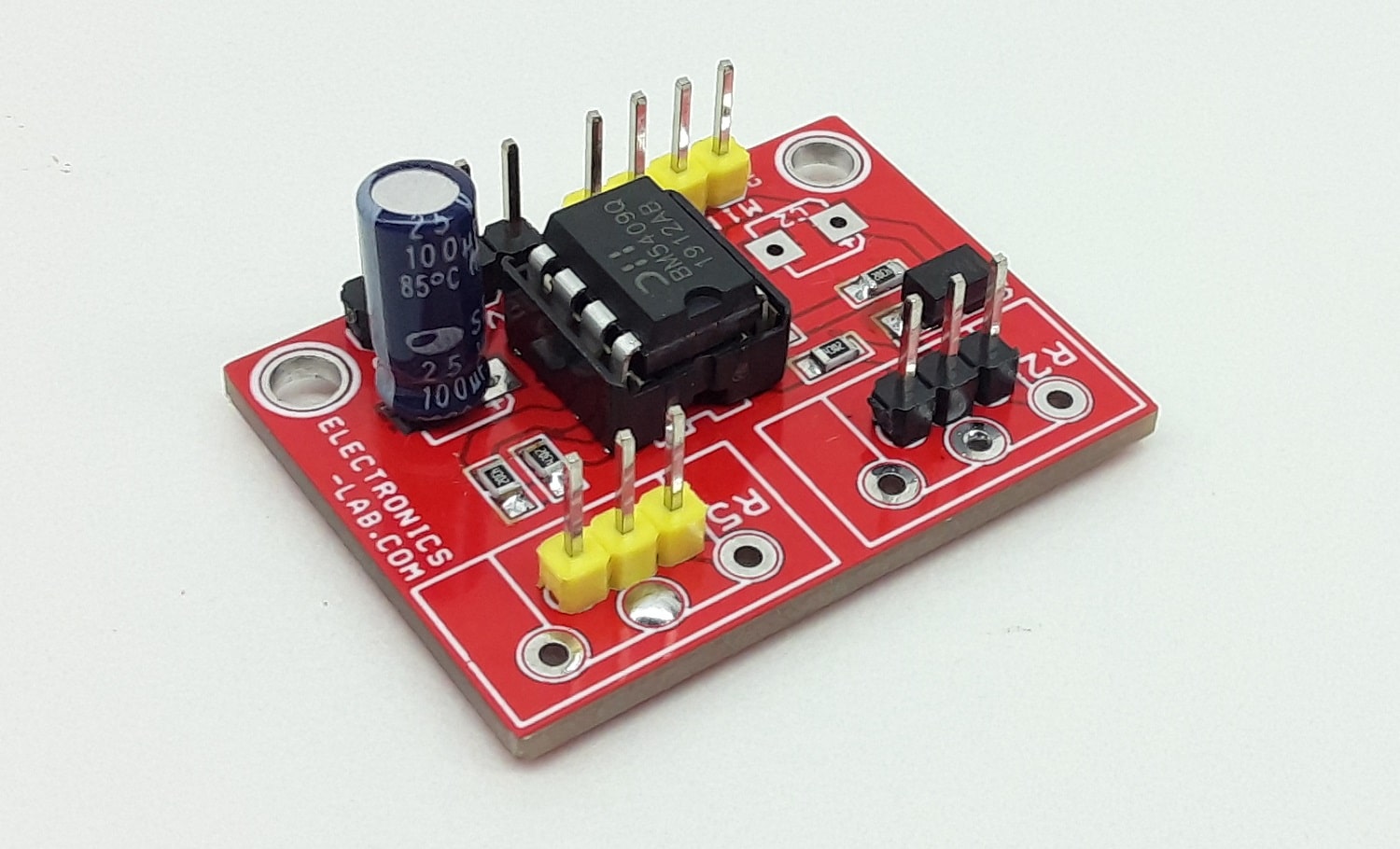

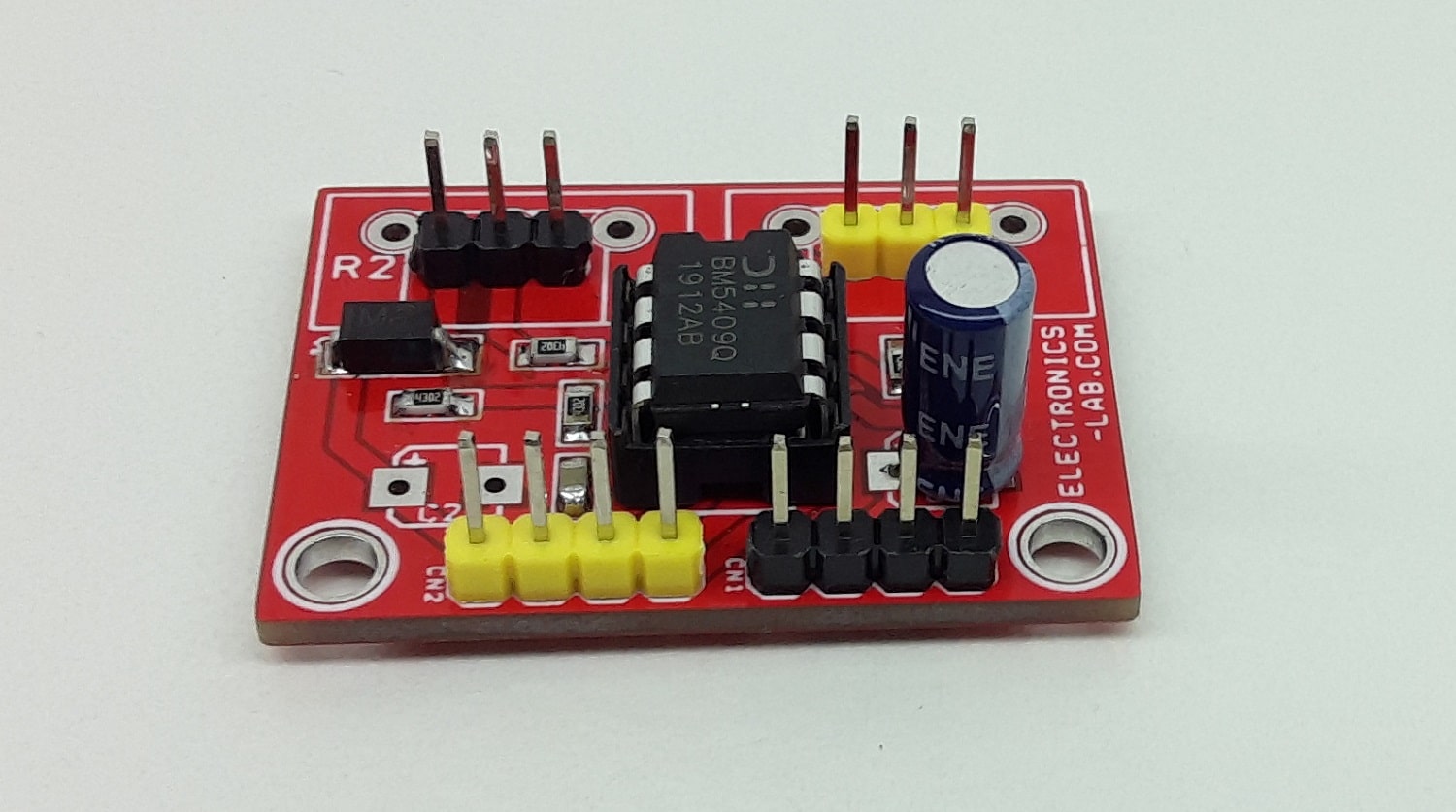

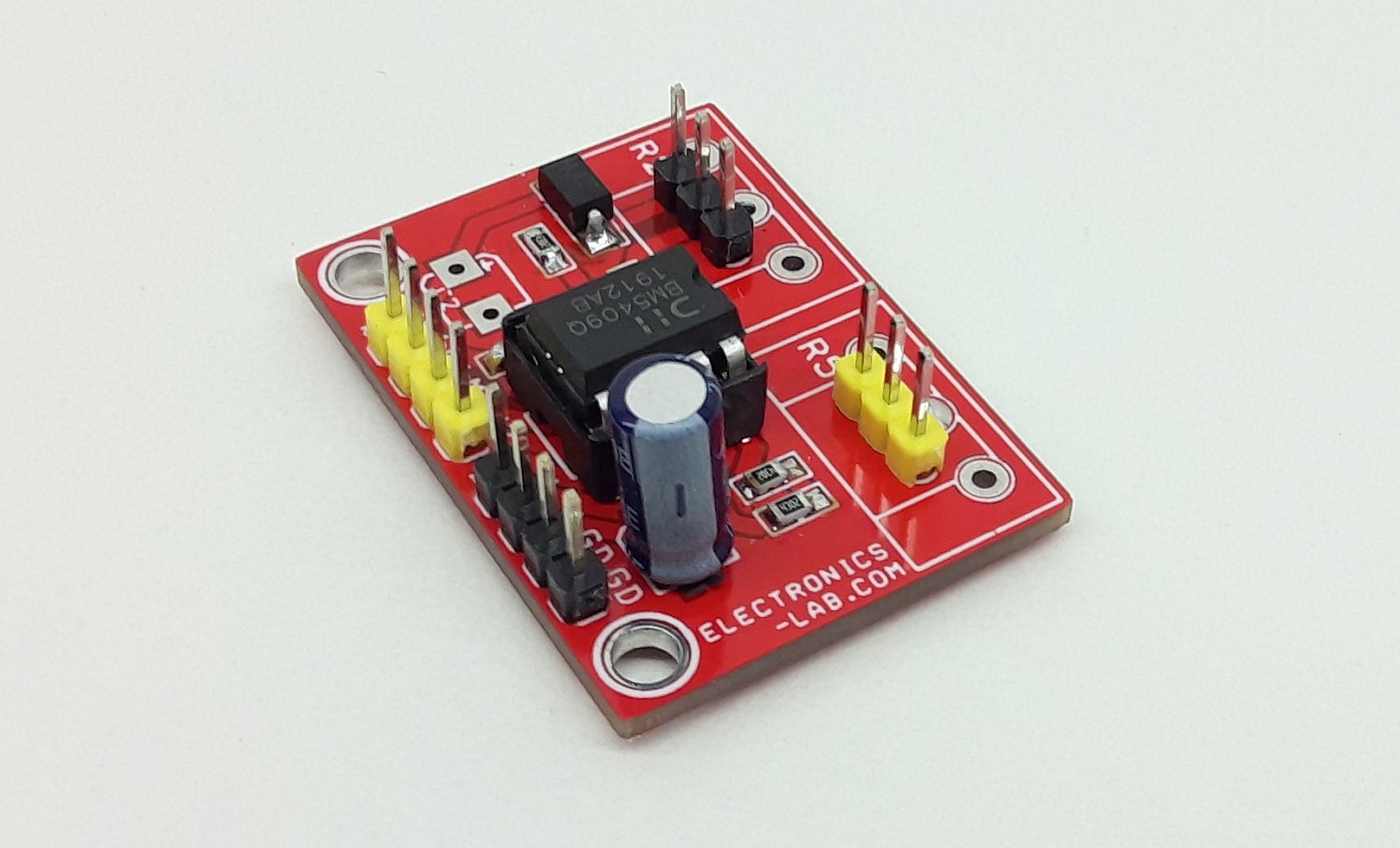

- SKU: EL114455

- Quote Now

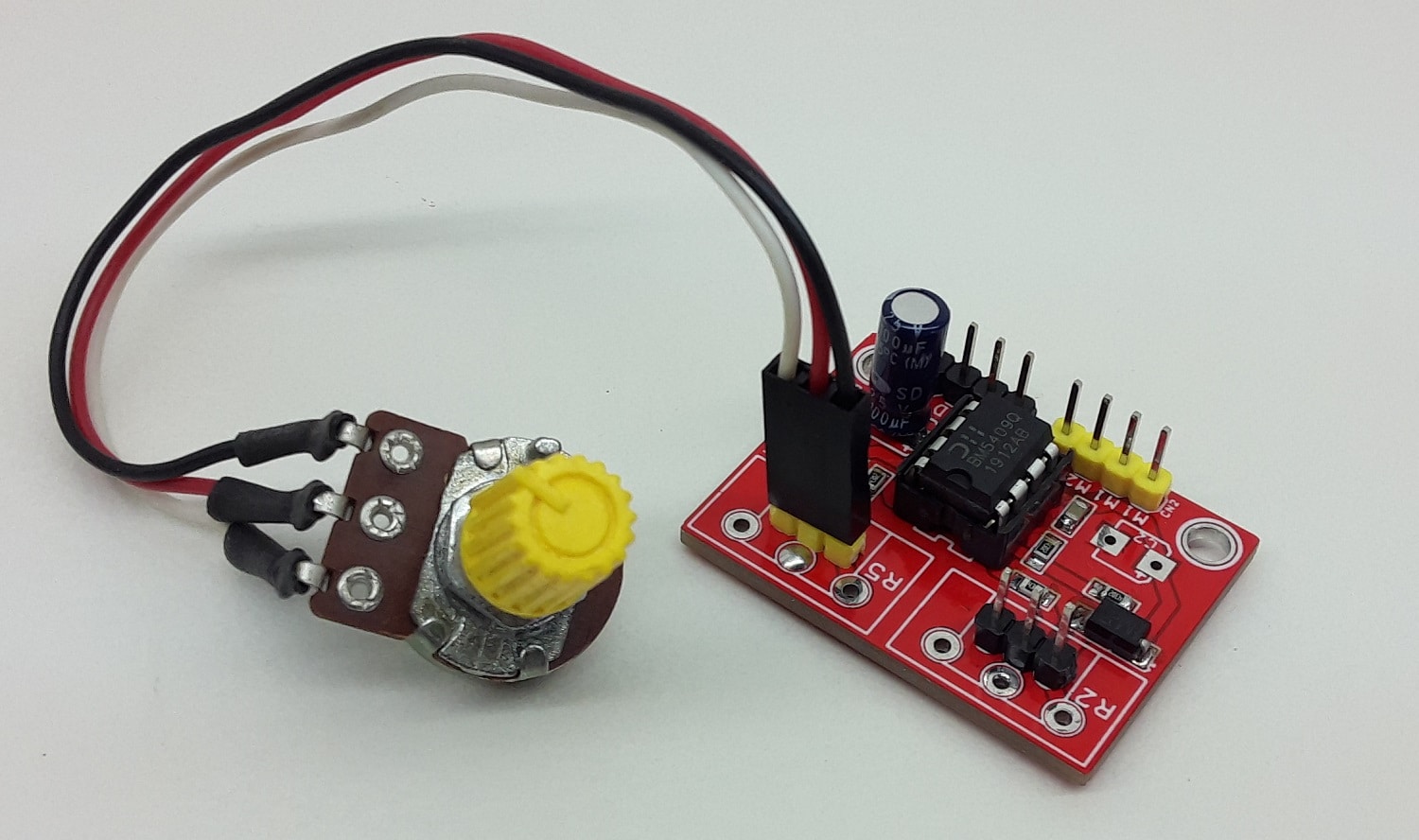

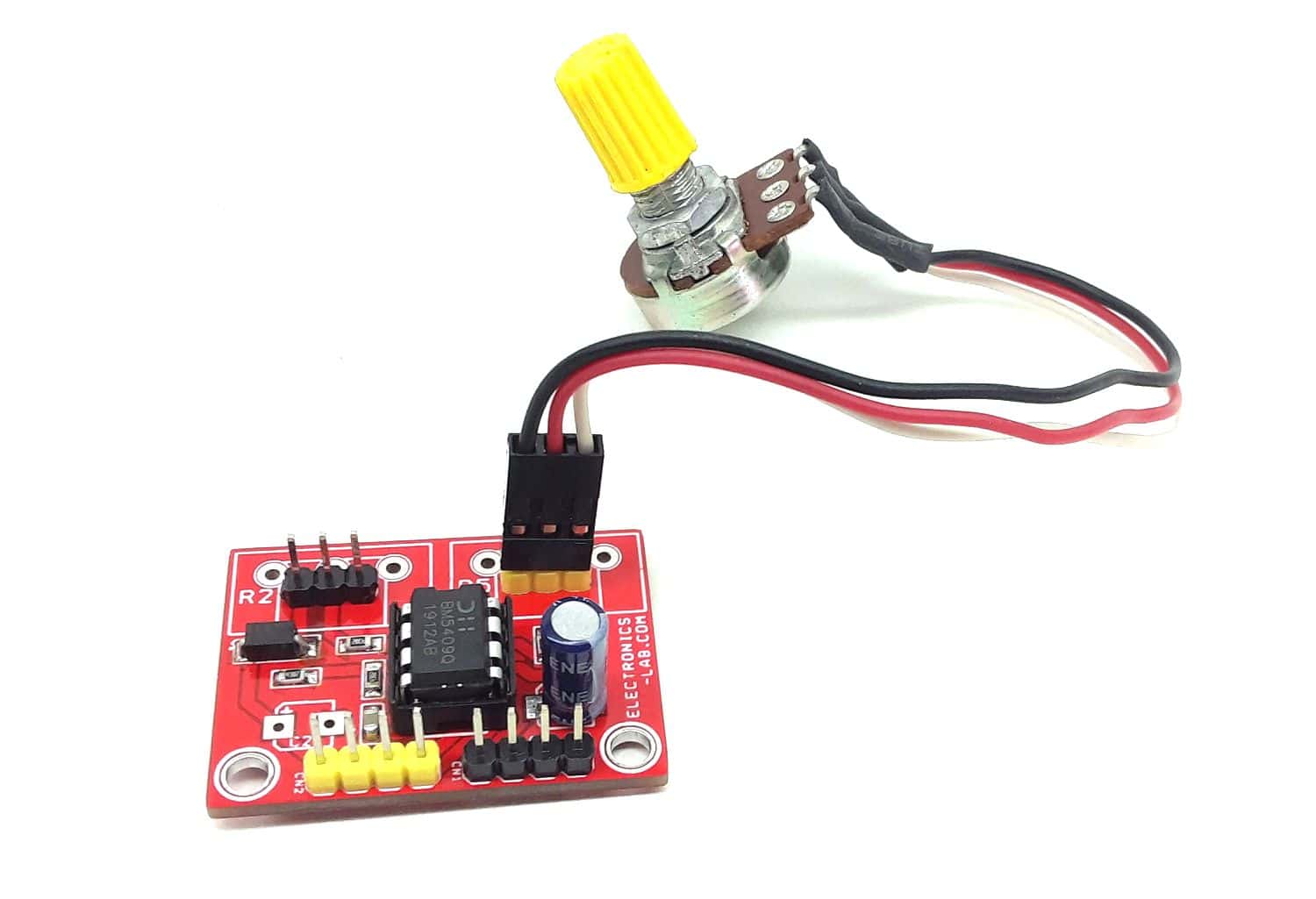

The project presented here is a low-cost position control closed-loop analog-servo using brushed DC motor and potentiometer as feedback. This project provides all necessary active functions for a closed-loop servo system using a Brushed DC Motor and potentiometer mounted on the output shaft of the DC Motor with Gear. The project is ideally suited for almost any servo positioning application. Can be used in applications such as side mirror movement control for cars, car head lamp beam control, animatronics, robotics, etc.

The project requires a special mechanism, where the DC motor’s output shaft is mechanically couple with the potentiometer shaft using a reduction gear. Approx. reduction ratio 15-50: 1. When the reference pot is turned, the motor shaft will follow the potion. This will provide a maximum rotation of 270 degrees. Multi rotation is possible with the help of a multiturn potentiometer.

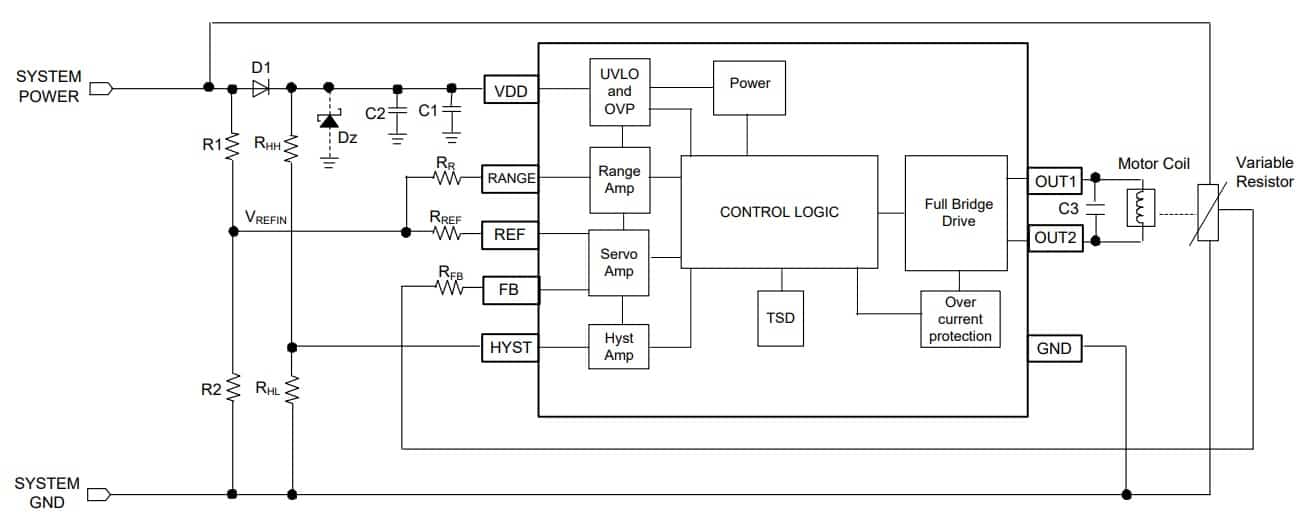

The project is based on the ZXBM5409Q chip from Diode Incorporation which is a protected H-bridge driver designed specifically for manual automotive headlight-beam control and industrial servo control applications with DC-brush motor loads. The integrated full-bridge driver output stage is composed of high-current, low-RDSON H-bridge MOSFETs to maximize efficiency. To simplify the circuit design and minimize external components, the device integrates voltage and temperature-compensated internal references, amplifiers, and output H-bridge power switches with low RDSON. For system flexibility, the servo controls forward and reverse hysteresis, dead band, and angle amplification are easily programmable by external resistors. To help protect the motor coil, the ZXBM5409Q provides fault condition protection, such as RANGE input short to GND, short-to supply voltage, or broken wires, by stopping the motor and disconnecting the output stage. In case of supply undervoltage and overvoltage, the device shuts down the output drive to help prevent overvoltage stress on the coil. The overcurrent protection monitors the output current and shuts down the outputs stage with periodic retry to help protect the coil from device burnout. Overtemperature shutdown provides thermal protection for the device.

Features

- Wide Operating Voltage Range: 8V to 18V

- Output Current 800mA (Peak 1.6A)

- Fault Protection – RANGE Short to GND, Supply, or Broken Wires

- Overvoltage and Undervoltage Shutdown

- Overcurrent Protection

- Thermal Protection

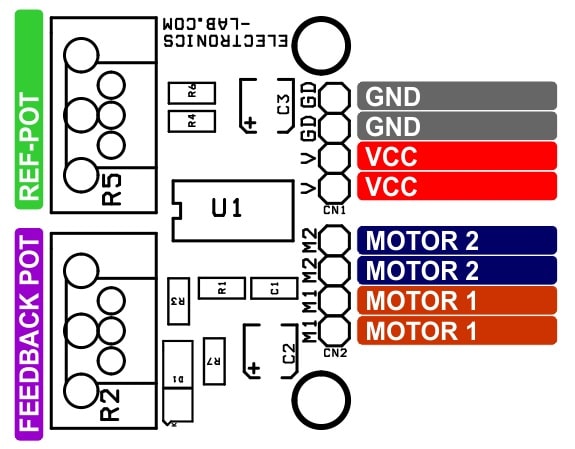

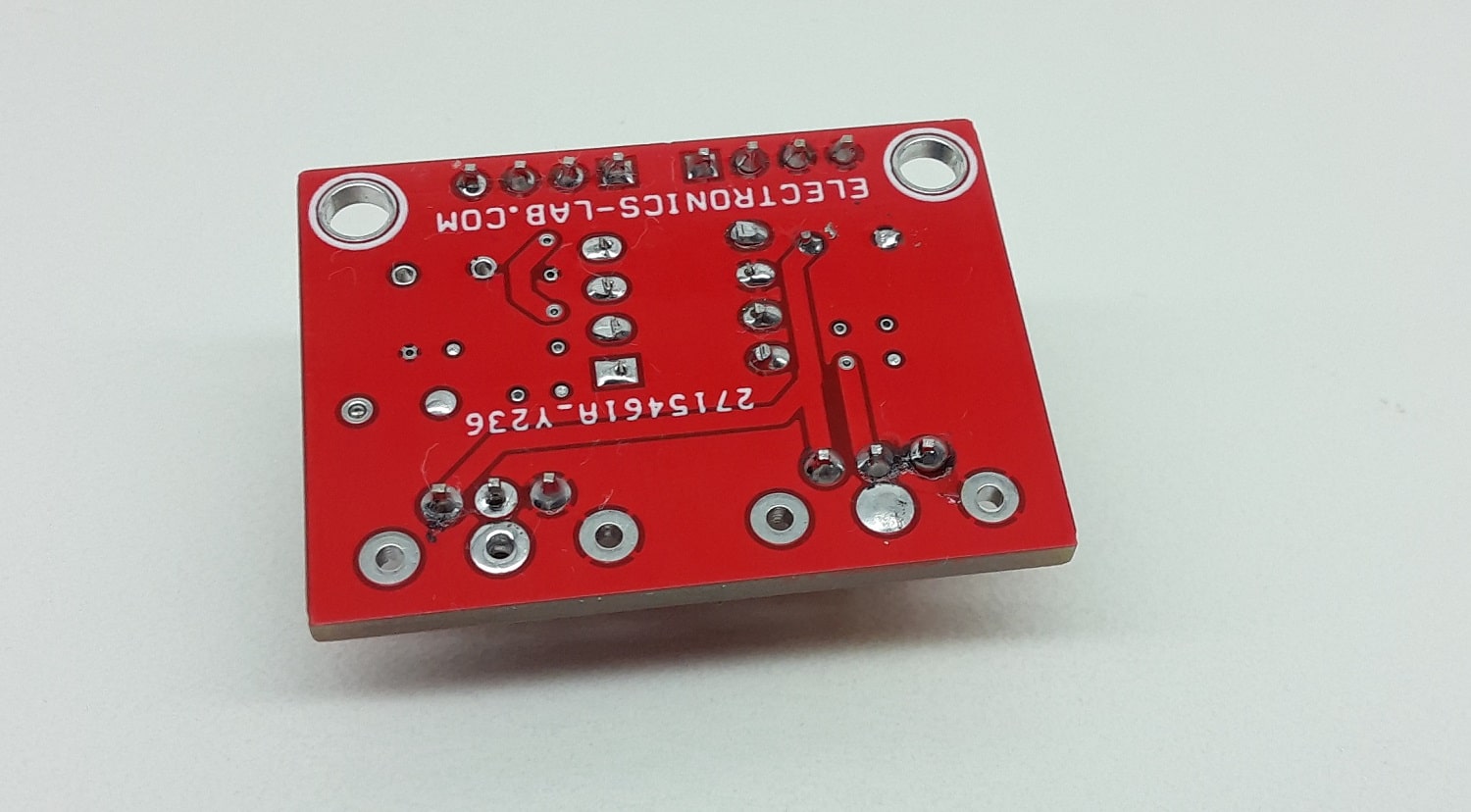

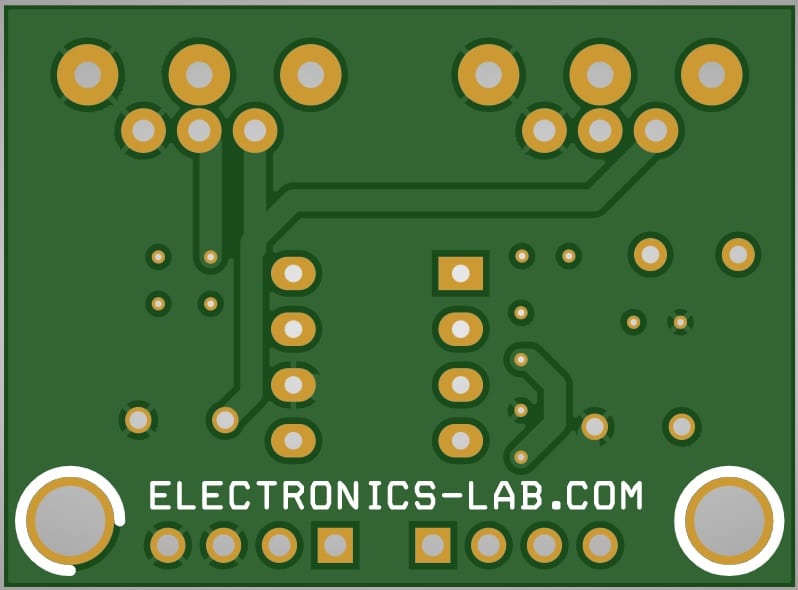

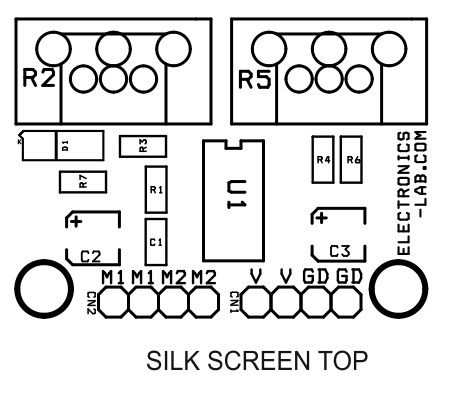

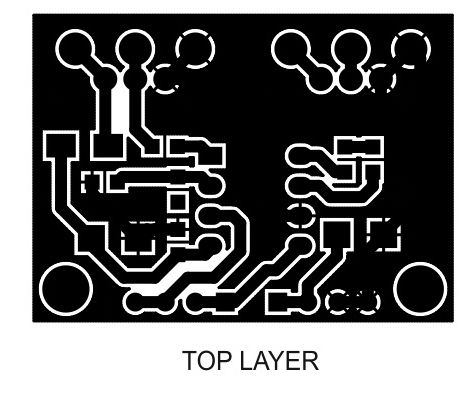

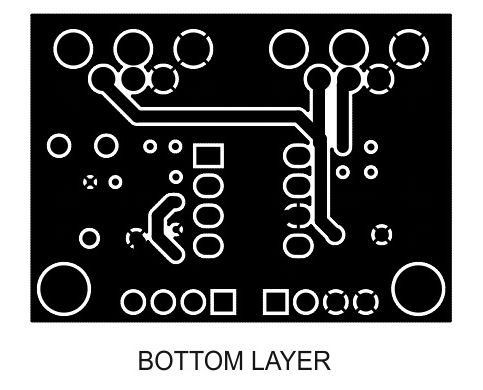

- PCB dimensions: 36.04 x 26.51 mm

Thermal Shutdown Protection

The device has an internal thermal shutdown to prevent a thermal runaway scenario. The thermal shutdown is triggered when the junction temperature of the device reaches +170°C. It will remain in standby mode until the junction temperature falls by +30°C.

Overcurrent Protection

The internal overcurrent protection (OCP) threshold is 1.6A typical at 12V supply +25°C. When the motor current exceeds the OCP threshold for longer than 2µs typical on any of the H-bridge switches, the device switches off all the output switches and remains off for 5ms typical. The IC returns to normal operation after the 200µs if overcurrent condition goes away. If the motor current is still higher than the OCP threshold, the device enters another 5ms standby mode.

Overvoltage Shutdown of Output Drive

When the supply voltage exceeds the overvoltage shutdown threshold, VOV_TH, the ZXBM5409Q shuts down all the output drive switches and enters standby mode to help prevent overvoltage stress on the coil. The driver returns to normal condition if the supply voltage drops below

VOV_RLTH—provided no other fault condition or signals are preventing it from entering normal operation

Undervoltage Lockout

To make sure the minimum voltage required to operate the driver is supplied, the ZXBM5409Q has an undervoltage lockout. At start up the device only starts if the supply voltage is typically over VUVLO_RLTH. During normal operation, the device switches off all the output switches and powers down if the supply voltage drops below VUVLO_TH typical. When the supply voltage drops below undervoltage lockout threshold, VUVLO_TH_R, the ZXBM5409Q shuts down all the output drive switches and enters standby mode to help prevent overvoltage stress on the coil.

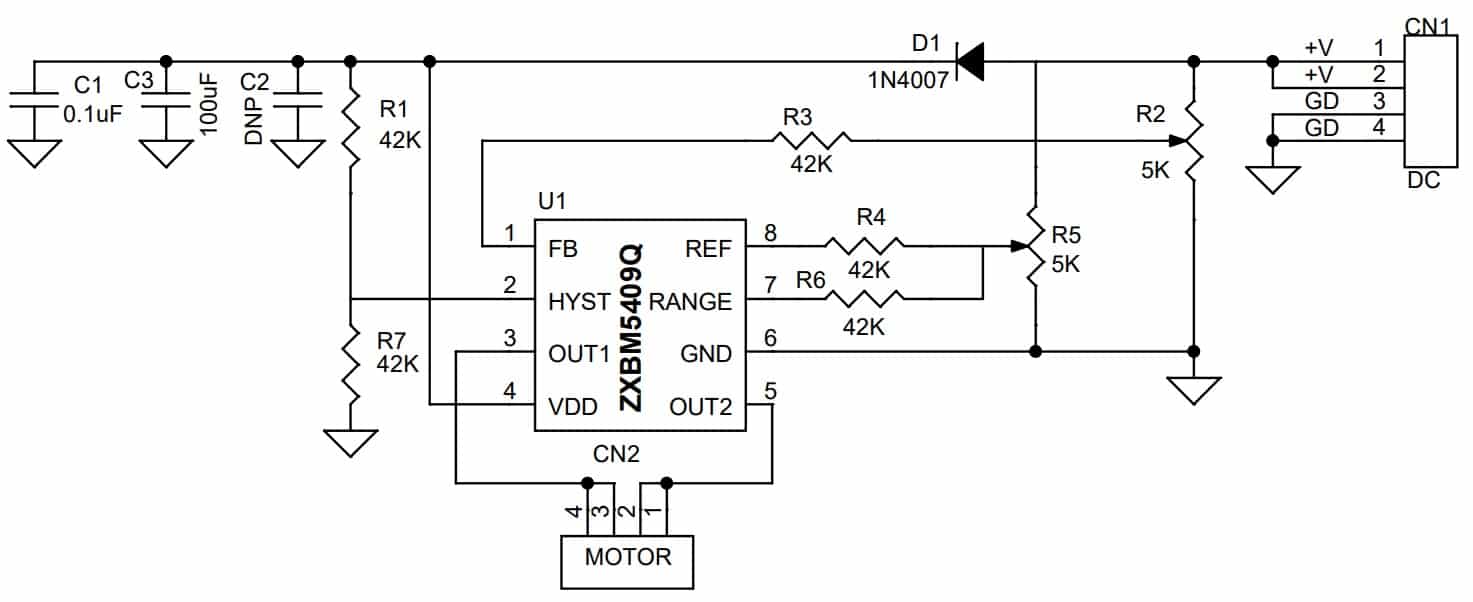

Schematic

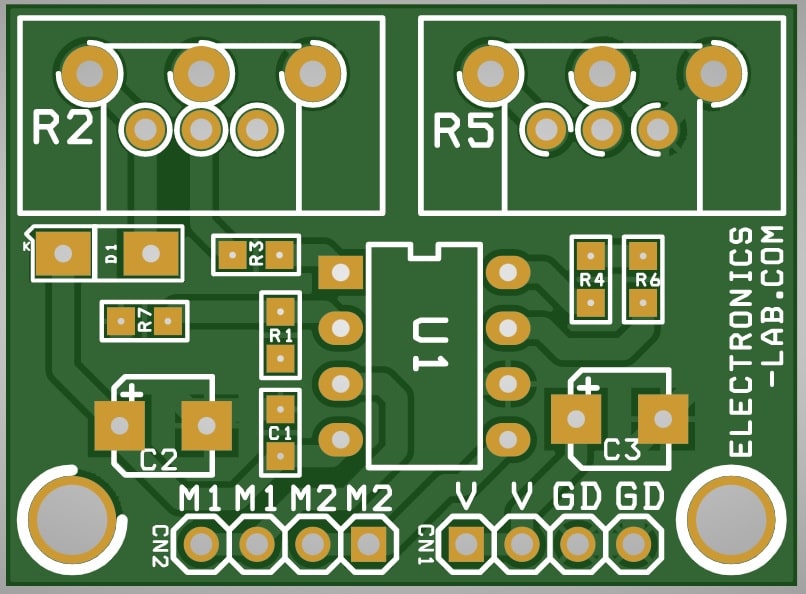

Parts List

| NO | QNTY | REF | DESC | MANUFACTURER | SUPPLIER | SUPPLIER PART NO |

|---|---|---|---|---|---|---|

| 1 | 1 | CN1 | 4 PIN MALE HEADER PITCH 2.54MM | WURTH | 732-5317-ND | |

| 2 | 1 | CN2 | 4 PIN MALE HEADER PITCH 2.54MM | WURTH | 732-5317-ND | |

| 3 | 1 | C1 | 0.1uF/50V SMD SIZE 0805 | MURATA/YAGEO | ||

| 4 | 1 | C2 | DNP | |||

| 5 | 1 | C3 | 100uF/25V ELECTROLYTIC | RUBYCON | DIGIKEY | 1189-4162-3-ND |

| 6 | 1 | D1 | 1N4007 SMD | SMC DIODE | DIGIKEY | 1655-1N4007FLCT-ND |

| 7 | 5 | R1,R3,R4,R6,R7 | 42K 1% SMD SIZE 0805 | MURATA/YAGEO | DIGIKEY | |

| 8 | 2 | R2,R5 | 5K POTENTIOMETER | BOURNS | DIGIKEY | PDB181-P415K-103B-ND |

| 9 | 1 | U1 | ZXBM5409Q | DIODE INC. | DIGIKEY | ZXBM5409Q-N-UDI-ND |

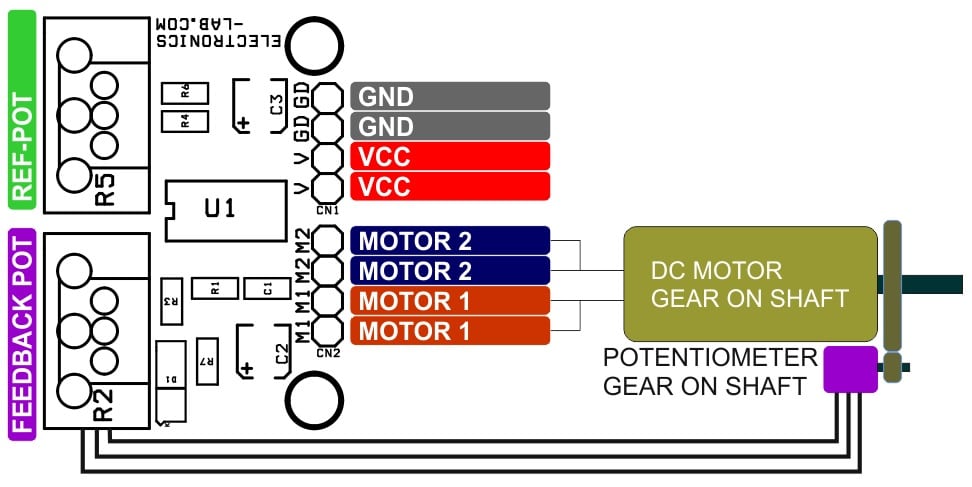

Connections

Block Diagram

Thank You !

That is what I want to say : Thank You !!!

This is exactly what I was longing for.

PID, arduino programming, and so on… For such a simple application, this solution is the simplest I came across so far.

As I have no skills in electronics at all, I still have two questions for you:

Thank you again for that share.

Best regards

Hi David and thanks for your kind words. As per your questions, you are right that C3 is directly connected to the +V and C1, C2 on the cathode of the diode. This is a little different than the schematic and it will not affect its function. Feel free to use the PCB implementation for a working board. The smaller possible motor to be used is a 8V one, you are right,

Hi Mike !

Thank you very much for your answer.

I’ll give you some news as soon as I assemble it.

Thank you again for your generosity!

Hi mixos,

I need a “Closed Loop Analog Position Control using Brushed DC Motor and Potentiometer” for a research work.

How can I buy this product from you?

I am waiting for your response.

Please click on green QUOTE button to request a quote for this board. Thanks

Can you do closed loop control of SG90 servo motor with potentiometer and arduino

Is this board still available? I sent a message for a quote but there was no reply.

Please fill out the quote form once again and be sure to include your correct email address. We aim to respond to all quotes in less than 8 hrs.

Thanks for your reply. I submitted a second request for a quote, and sent an email with a couple of questions.

I didn’t get your quote. Please complete the form correctly and hit send. Also, you will have to check the CAPTCHA.

I did that both times, and it said that it was sent. I have two questions.

1. The schematic shows two 5K potentiometers but the video shows a motorized 10K potentiometer. Could I use two 10K potentiometers instead of 5K potentiometers?

2. I want to control two DC motors. Could an H bridge be used or is there another way to do this?

I also replied to your email, did you get the quote ?

I received the quote for 10 boards. I could use one or two but it will be an expensive investment to have 8 spare boards. I understand that the minimum order is for 10 boards. I need the boards for a project that I’m working on but it’s hard to spend money on parts that aren’t being used. Please let me know if there are other options to obtain a smaller quantity.

The only option will be to build it on your own as all details are available on this page.

Hi. I assembled the curcuit on a breadboard but didn’t have good results. The motor has random operation instead of smooth, linear movement. It will sometimes hum, and get caught if the potentiometer is moved abruptly. It only moves a few degrees to the left & right but will not move very far. The motor is a small 5 volt motor. The power supply has close to 13 volts. A larger 18 volt motor was tested but the motor did not move at it. It only hummed. Is an internal safety in the chip preventing it from operating properly?