DC Motor Position Control Using Potentiometer – Arduino Compatible

- Rajkumar Sharma

- 875 Views

- medium

- Tested

- SKU: EL138890

- Quote Now

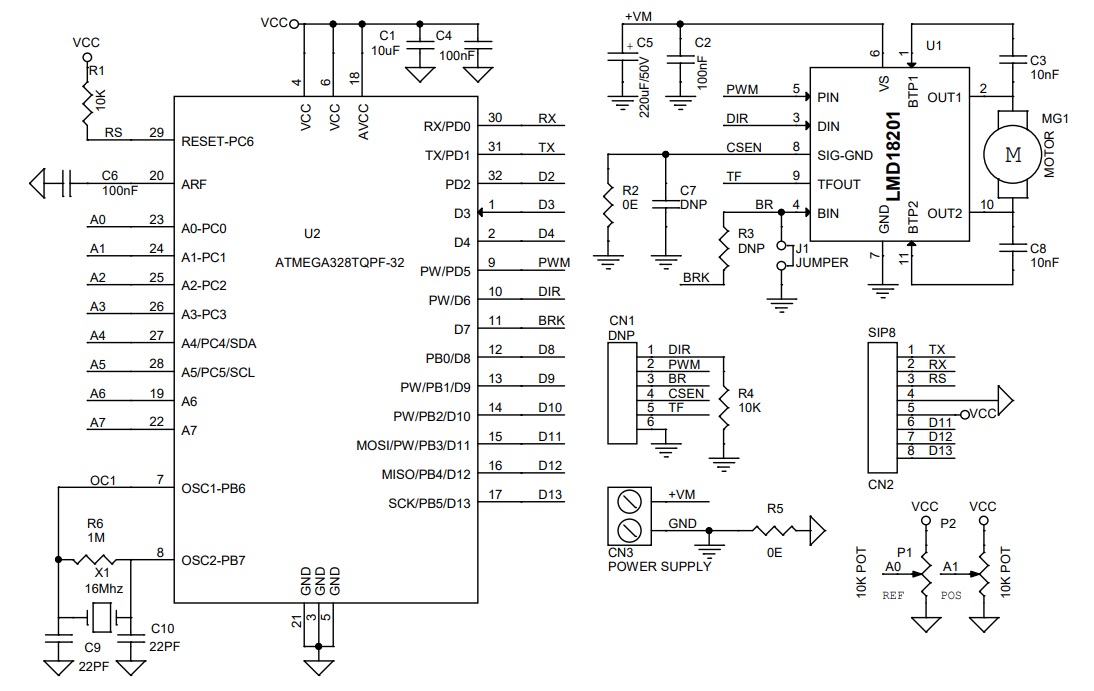

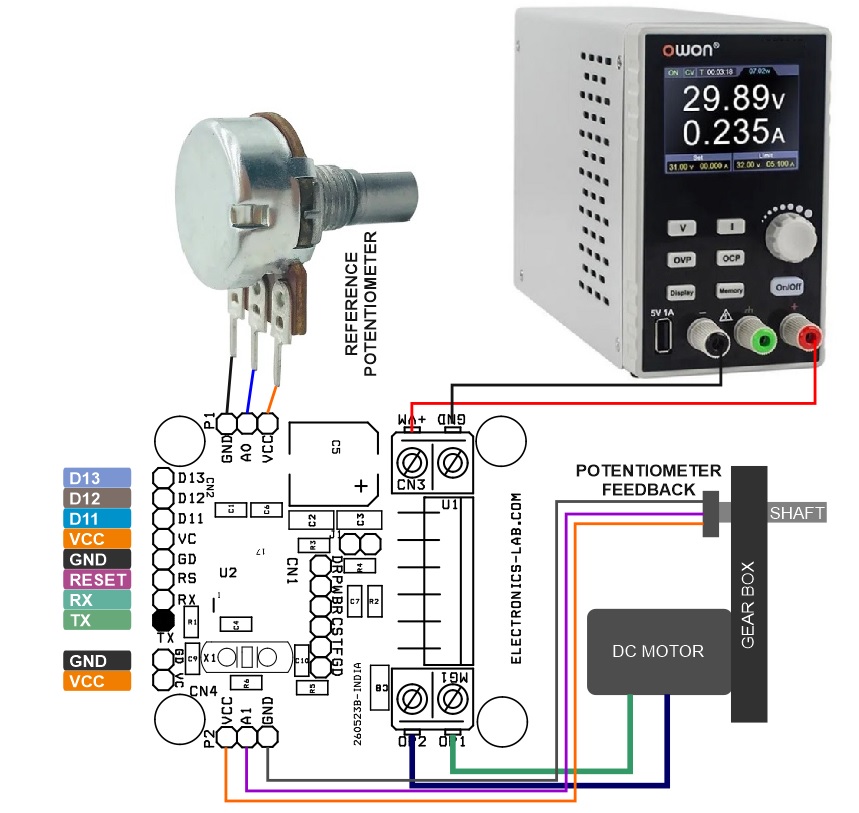

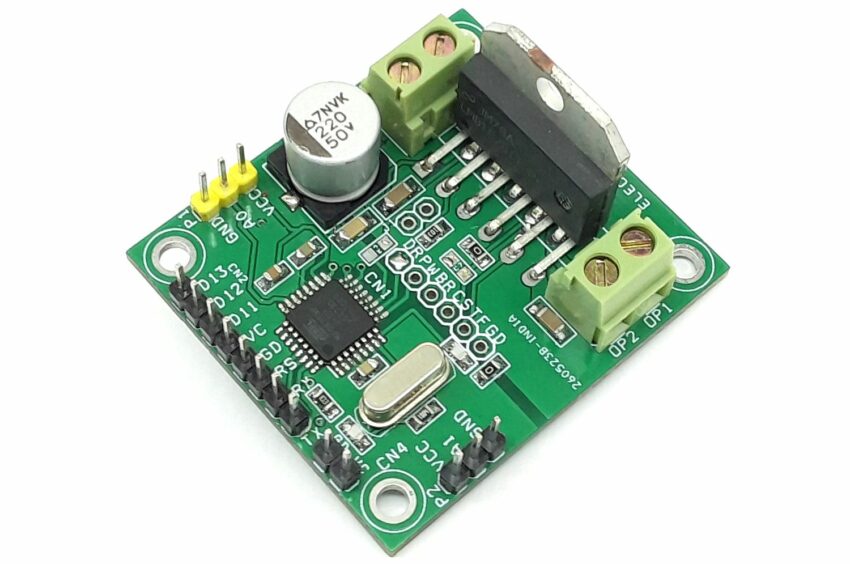

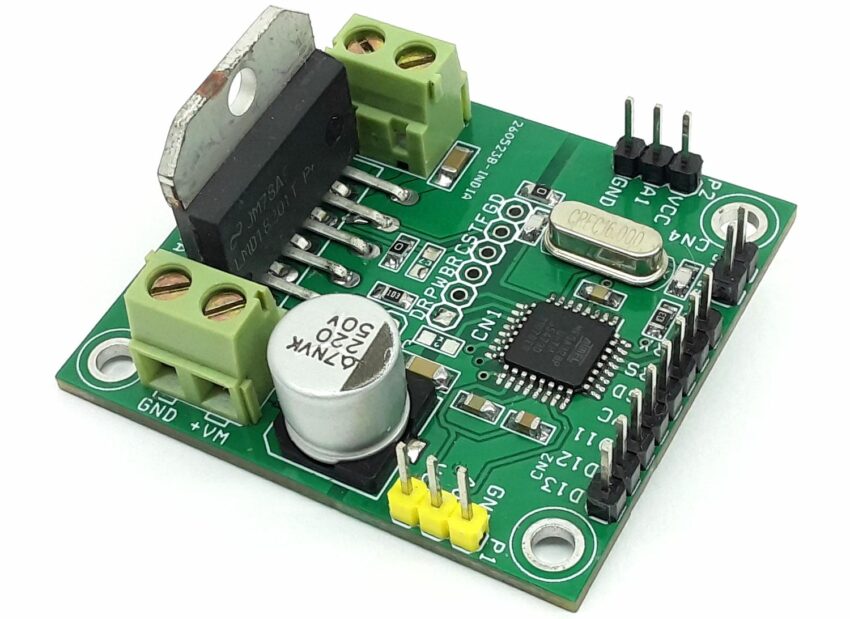

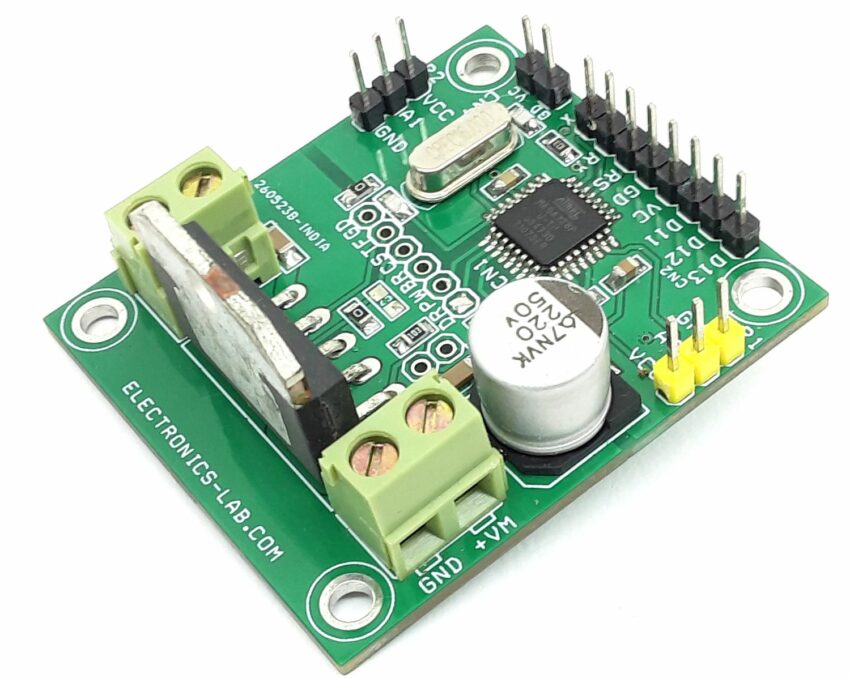

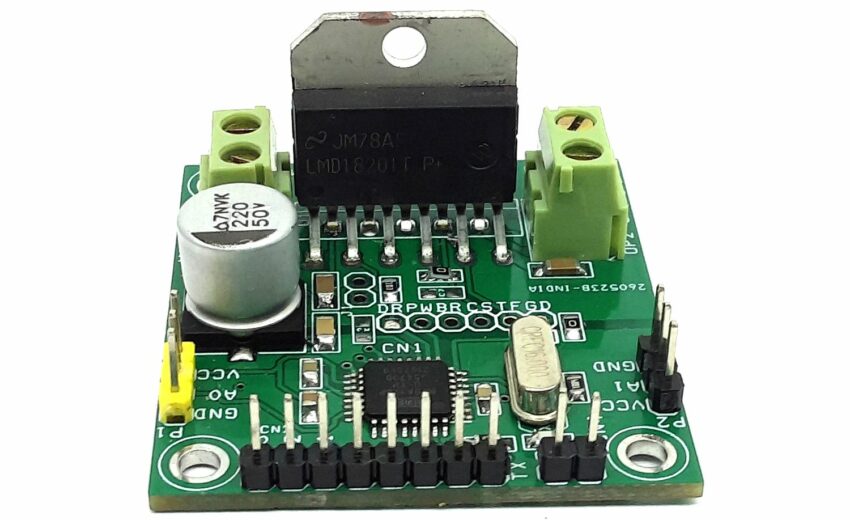

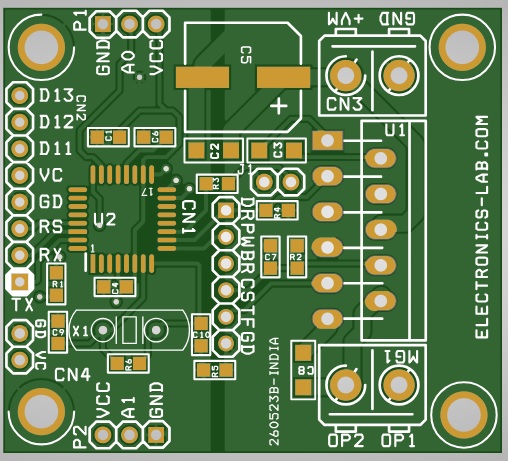

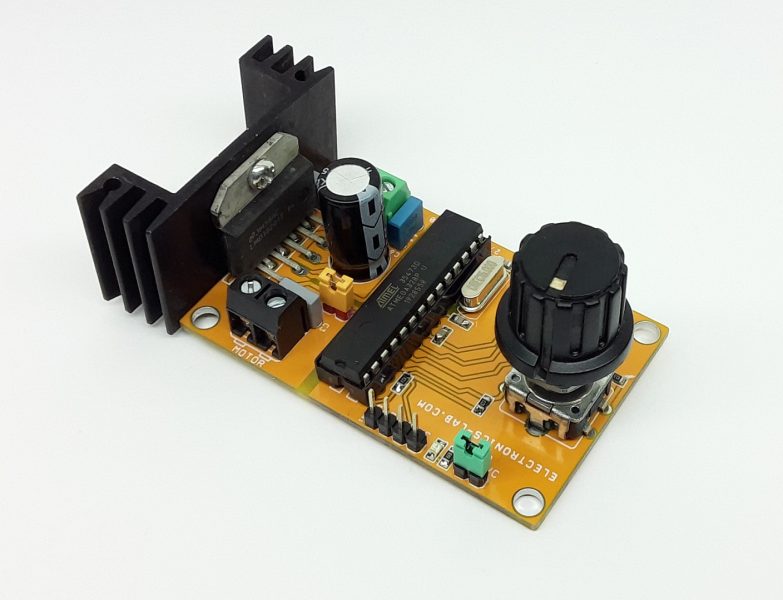

The project presented here is an Arduino-compatible motor control board. The board consists of an ATMEGA328 microcontroller, LMD18201 H-Bridge, and 2 x potentiometers. This closed-loop servo system provides position control using a feedback potentiometer mounted on the output shaft of the gearbox and provides position control by turning the shaft of the reference potentiometer, the motor-gearbox output shaft follows the reference potentiometer. The project can also be used in other applications that require Arduino-compatible hardware and H-Bridge.

The project requires a special mechanism, where the DC motor’s output shaft is mechanically coupled with the potentiometer shaft using a reduction gear. Approx. reduction ratio 15-50: 1. When the reference pot is turned, the motor shaft follows the position. This will provide a maximum rotation of 270 degrees. Multi-rotation is possible with the help of a multiturn potentiometer.

Arduino Code

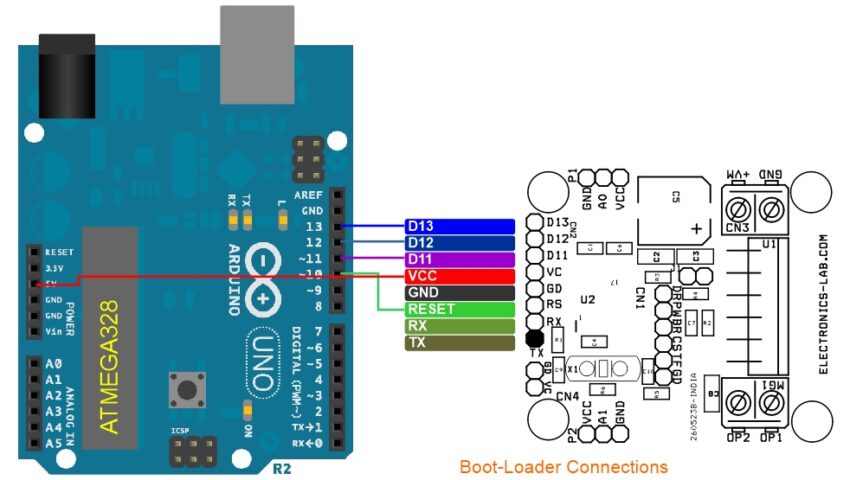

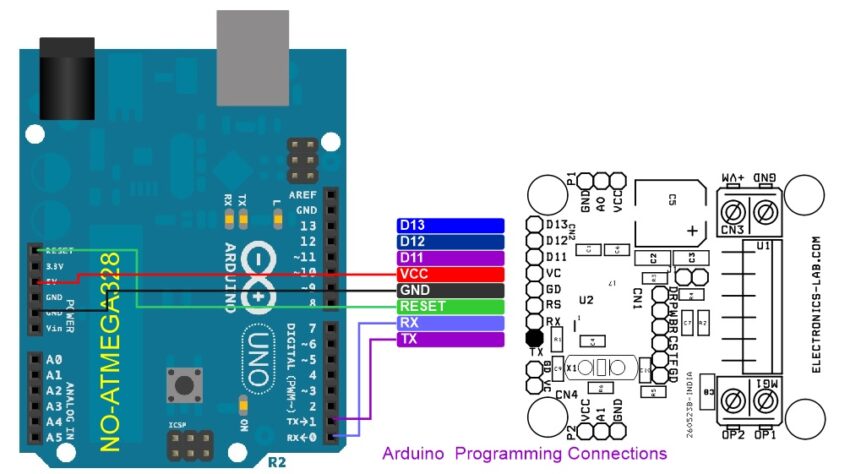

Arduino example code is available and the board can be programmed using the CN2 connector, the same connector helps burn the boot-loader to a new ATMEGA328 chip.

Refer to the following link for more info about Arduino programming: https://docs.arduino.cc/built-in-examples/arduino-isp/ArduinoToBreadboard

This is a modified code, original author of the code: http://geekeeceebee.com

Arduino Pins vs H-Bridge LMD18201

- Arduino D5 = PWM

- Arduino D6 = Direction

- Arduino D8 = Brake (Not Used -Optional)

- Arduino A0 Reference Potentiometer, A1 Feedback Potentiometer

Features

- Power Supply Motor 12V to 40V (48V Max)

- Motor Load 3A (Peak 6A)

- Logic Supply 5V DC @ 20mA

- On Board Jumper J1 for Brake, Closed for Normal Operations

- On Board Programming Connector for Arduino IDE

- Screw Terminals for Motor and Power Supply

- 2 X 3 Pin Male Header for Feedback and Reference Potentiometers

- Arduino Compatible

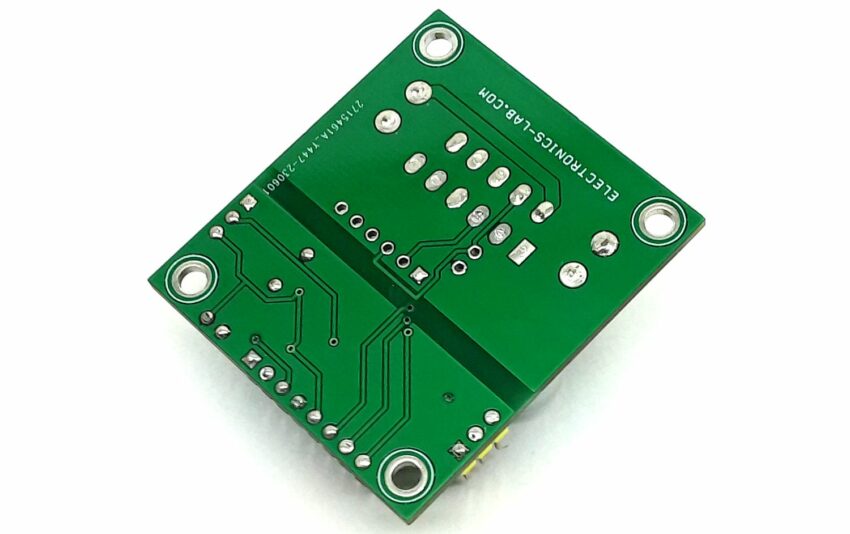

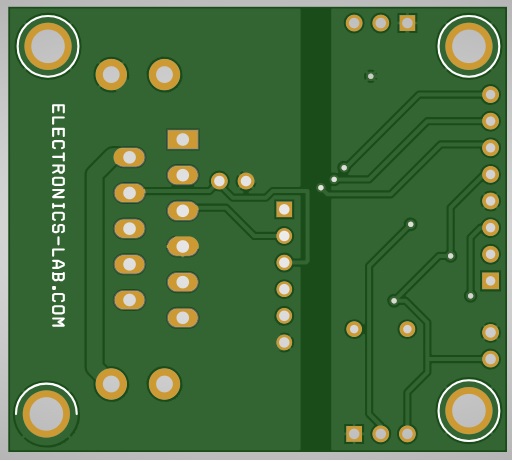

- PCB Dimensions 47.63 x 42.55mm

- 4 x 3MM Mounting Holes

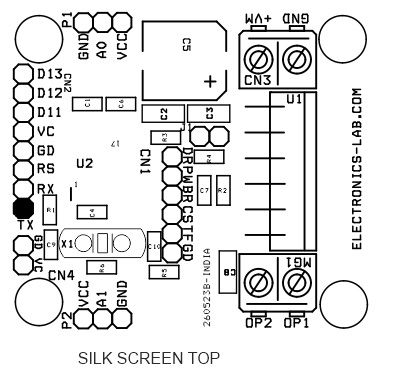

Connection & Other Details

- CN1: Optional Do Not Install

- CN2: Programming Connector Pin 1 = Tx, Pin 2 = Rx, Pin 3 = Reset, Pin 4 = GND, Pin 5 = VCC, Pin 6 = D11, Pin 7 = D12, Pin 8 = D13

- CN3: Pin 1 = Motor Power Supply, Pin 2 = GND

- MG1: Pin 1 = Motor 1, Pin 2 = Motor 2

- P1: Reference Potentiometer

- P2: Feedback Potentiometer

- J1: the jumper must be closed to enable the Brake for normal operation.

Schematic

Parts List

| NO | QNTY | REF | DESC | MANUFACTURER | SUPPLIER | SUPPLIER PART NO |

|---|---|---|---|---|---|---|

| 1 | 3 | CN1,R3,C7 | DNP | |||

| 2 | 1 | CN2 | 8 PIN MALE HEADER PITCH 2.54MM | WURTH | 732-5321-ND | |

| 3 | 1 | CN3 | 2 PIN SCREW TERMINAL PITCH 5.08MM | PHOENIX | 277-1247-ND | |

| 4 | 1 | C1 | 10uF/10V CERMIC SMD SIZE 0805 | YAGEO/MURATA | ||

| 5 | 3 | C2,C4,C6 | 100nF/50V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | ||

| 6 | 2 | C3,C8 | 10nF/50V CERAMIC SMD SIZE 1206 | YAGEO/MURATA | ||

| 7 | 1 | C5 | 220uF/50V | RUBYCON | 1189-1654-1-ND | |

| 8 | 2 | C9,C10 | 22PF/50V CERAMIC SMD SIZE 0805 | YAGEO/MURATA | ||

| 9 | 1 | J1 | 2 PIN MALE HEADER PITCH 2.54MM | WURTH | 732-5315-ND | |

| 10 | 1 | MG1 | 2 PIN SCREW TERMINAL PITCH 5.08MM | PHOENIX | 277-1247-ND | |

| 11 | 2 | P1,P2 | 10K POTENTIOMETER | CTS ELECTRO | CT2159-ND | |

| 12 | 2 | R1,R4 | 10K 5% SMD SIZE 0805 | YAGEO/MURATA | ||

| 13 | 2 | R2,R5 | 0E SMD SIZE 0805 | YAGEO/MURATA | ||

| 14 | 1 | R6 | 1M 5% SMD SIZE 0805 | YAGEO/MURATA | ||

| 15 | 1 | U1 | LMD18201 | TI | LMD18201T/NOPB | |

| 16 | 1 | U2 | ATMEGA328TQPF-32 | MICROCHIP | ATMEGA328PB-AURCT-ND | |

| 17 | 1 | X1 | 16Mhz | ECS INC | X1103-ND | |

| 18 | 1 | JUMP | SHUNT FOR JUMPER J1 | SULLINS CONNECT | S9001-ND |

Connections

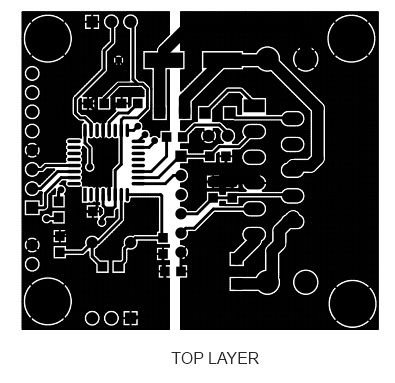

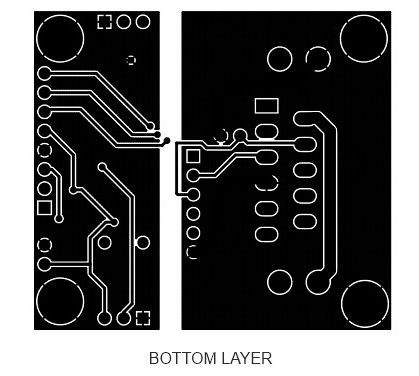

Gerber View

Code

//GeeKee CeeBee

// ************ DEFINITIONS************

int potPin = A0; // Reference Potentiometer

int encoder_pot = A1; // Position Feedback sensor

int val = 0;

int encoder_val =0;

float kp = 0.2;

float ki = 0.00000 ;

float kd = 2.00;

float Theta, Theta_d;

int dt;

unsigned long t;

unsigned long t_prev = 0;

int val_prev =0;

float e, e_prev = 0, inte, inte_prev = 0;

float Vmax = 12;

float Vmin = -12;

float V = 0.1;

const byte PWMPin = 5;

const byte DirPin1 = 6;

const byte DirPin2 = 8;

//***Motor Driver Functions*****

void WriteDriverVoltage(float V, float Vmax) {

int PWMval = int(255 * abs(V) / Vmax);

if (PWMval > 255) {

PWMval = 255;

}

if (V > 0) {

digitalWrite(DirPin1, HIGH);

digitalWrite(DirPin2, LOW);

}

else if (V < 0) {

digitalWrite(DirPin1, LOW);

digitalWrite(DirPin2, HIGH);

}

else {

digitalWrite(DirPin1, LOW);

digitalWrite(DirPin2, LOW);

}

analogWrite(PWMPin, PWMval);

}

void setup() {

Serial.begin(9600);

pinMode(DirPin1, OUTPUT);

pinMode(DirPin2, OUTPUT);

}

void loop() {

val = analogRead(potPin); // Read V_out from Reference Pot

encoder_val =analogRead(encoder_pot); // Read V_out from Feedback Pot

t = millis();

dt = (t - t_prev); // Time step

Theta = val; // Theta= Actual Angular Position of the Motor

Theta_d = encoder_val; // Theta_d= Desired Angular Position of the Motor

e = Theta_d - Theta; // Error

inte = inte_prev + (dt * (e + e_prev) / 2); // Integration of Error

V = kp * e + ki * inte + (kd * (e - e_prev) / dt) ; // Controlling Function

if (V > Vmax) {

V = Vmax;

inte = inte_prev;

}

if (V < Vmin) {

V = Vmin;

inte = inte_prev;

val_prev= val;

}

WriteDriverVoltage(V, Vmax);

Serial.println(Theta_d); Serial.print(" \t");

Serial.print(Theta); Serial.print(" \t ");

t_prev = t;

inte_prev = inte;

e_prev = e;

delay(10);

}

Photos

Video