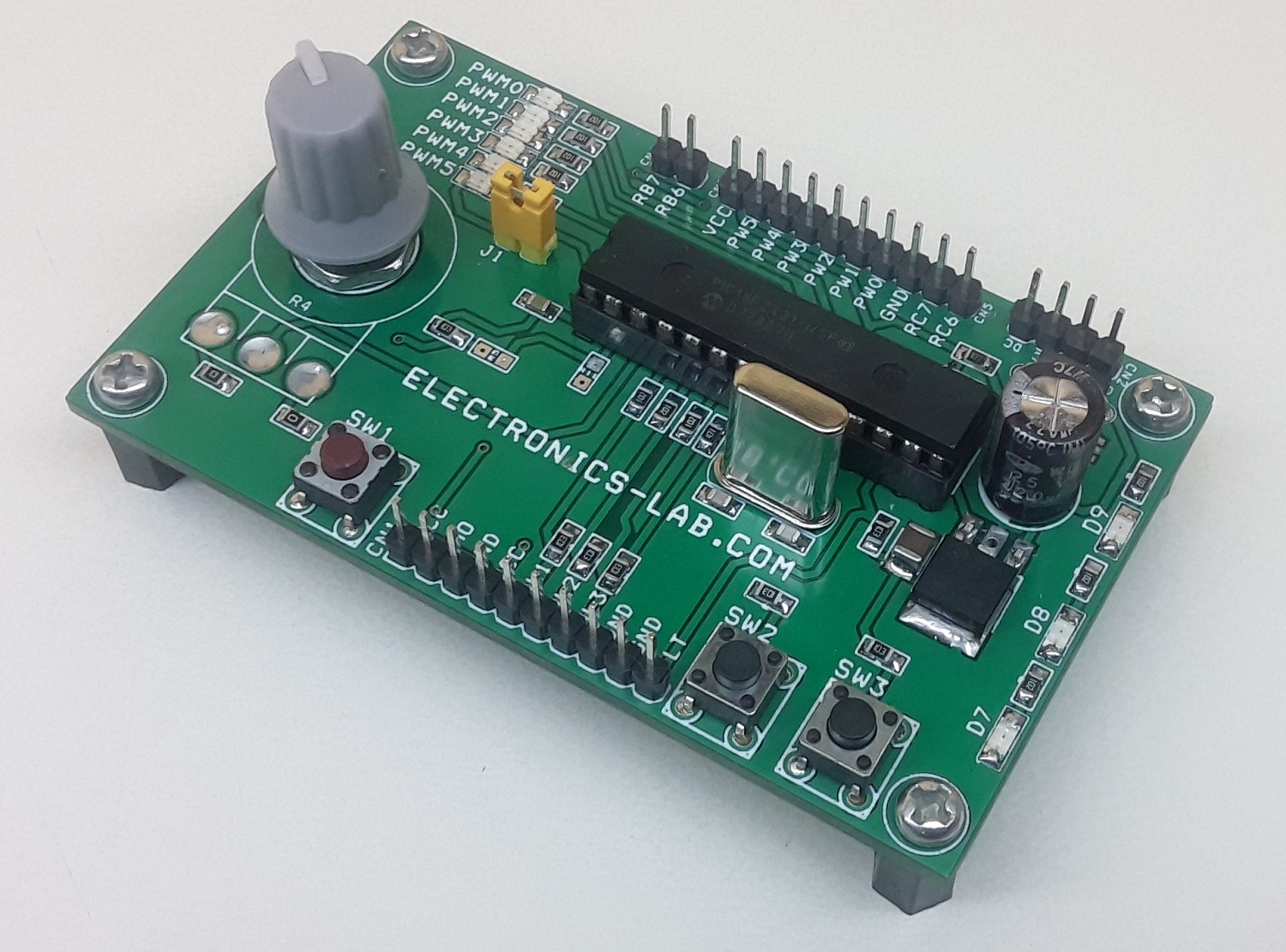

Development board for Brushless Motor, DC Brushed Motor, AC Motors (Pre-Driver)

- Rajkumar Sharma

- 983 Views

- medium

- Tested

- SKU: EL111995

- Quote Now

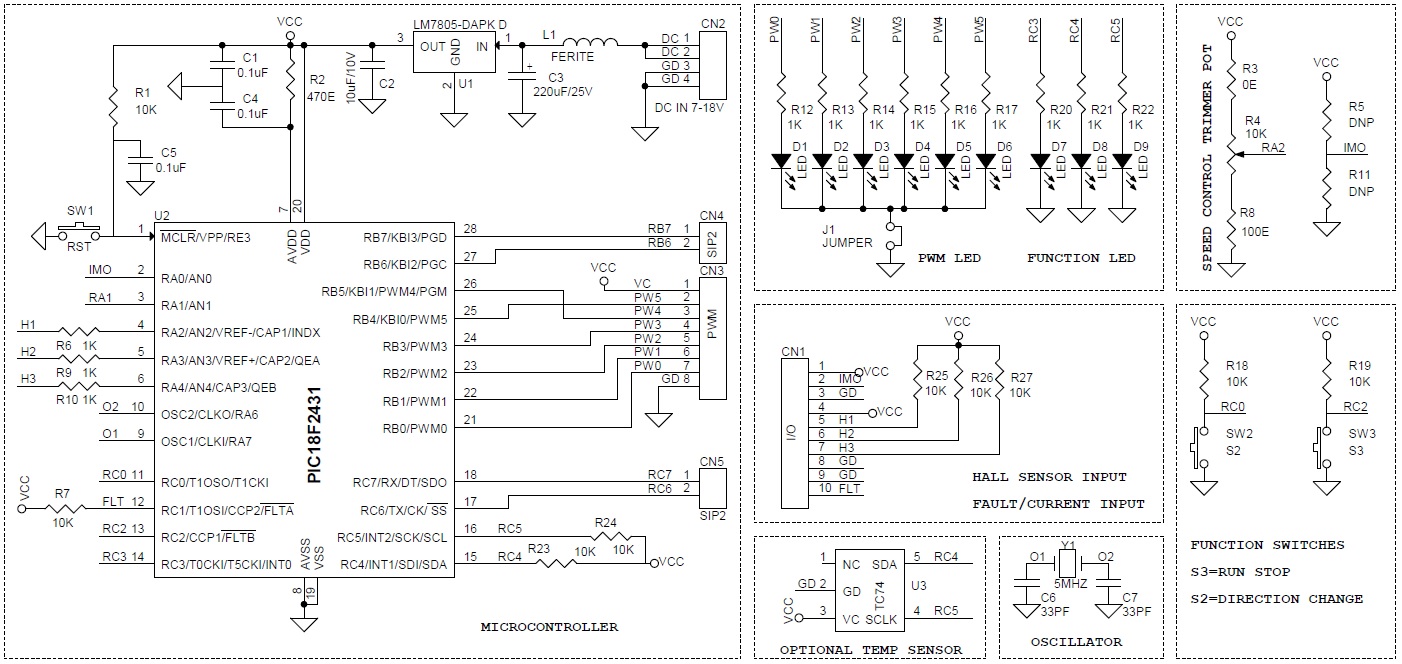

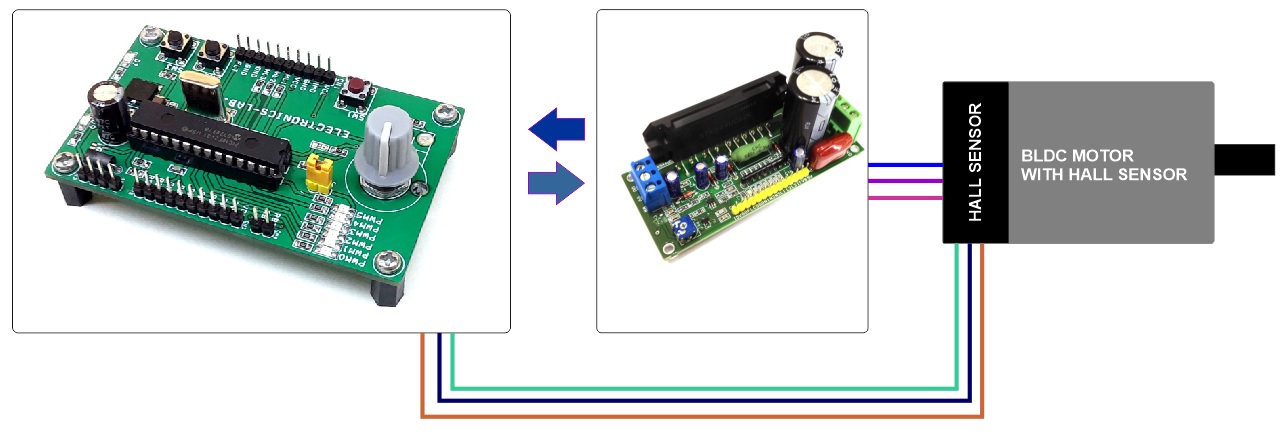

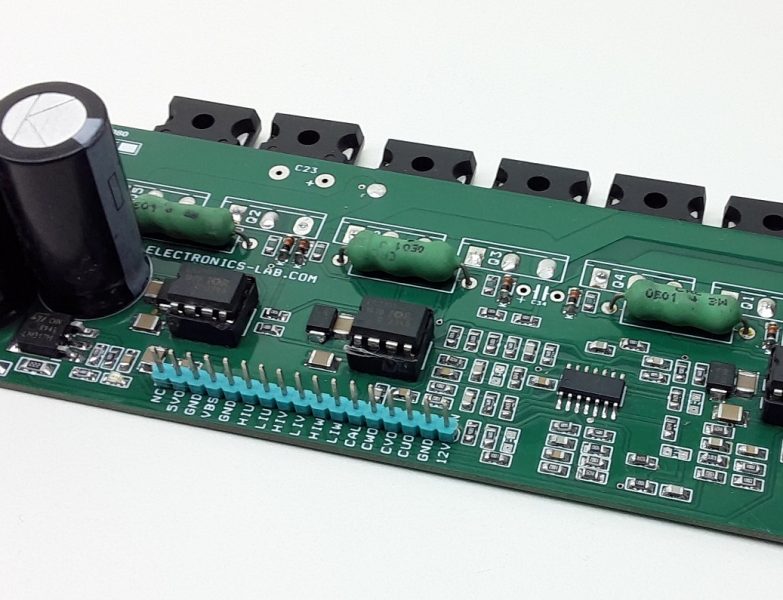

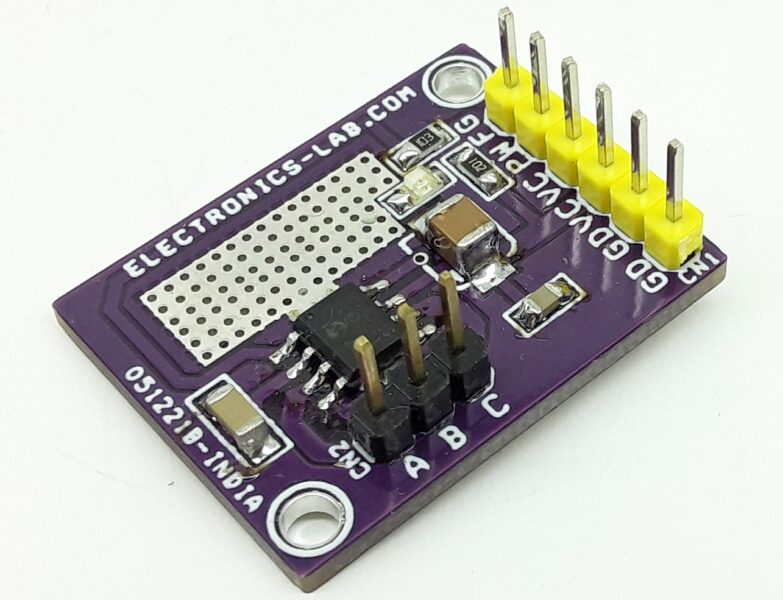

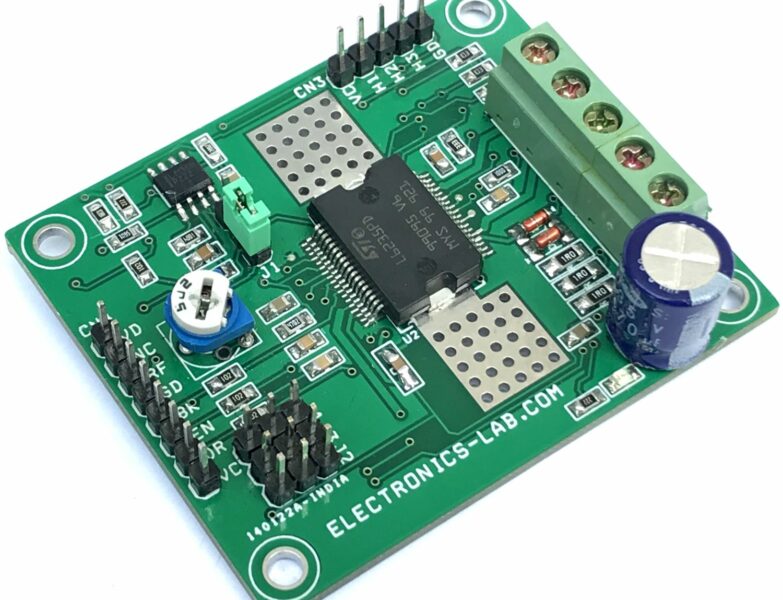

The project described here is a pre-driver for brushless motors with a hall sensor. The board incorporates many features like current monitor, fault, speed control, direction control motor start/stop using tactile switches, various function LEDs, 6 PWM LEDs. By combining it with a hybrid IC or IPM module large size high voltage and high current motor can be driven. The project is compatible with the Microchip PICDEM MCLV motor development board, HEX firmware of the MCLV board can directly work with this board. This board is mainly targeted to control brushless DC (BLDC) motors in hall sensor operations. The board supports a free, ready-to-use MC-GUI (Motor Control – Graphical User Interface) from Microchip. Using the MC-GUI, the user can easily set and/or change motor parameters. This greatly helps the user in developing customized drive solutions. Temperature sensor chip U3 is optional so do not populate. The fault pin has to be high for normal operation, bring it to GND to disable the operations. This pin can be used as over current input from ITRIP pin or an over-current comparator of the IPM module. Overcurrent can be monitored using the IMO (RA0) pin of IC in the range 0 to 3V. PWM Frequency default 20Khz with example HEX code. Hex code is available as a download.

This flexible and low-cost board can be configured in different ways to use with Microchip’s specialized motor control microcontrollers. This low-cost board has the facility to use either the PIC18F2331/2431, this hardware can be used to drive AC motor, Brush DC motor, Brushless DC motor, and solenoid. Various inputs and outputs pins are available, microcontroller has dedicated 8 power module PWM, Motion feedback Optical encoder or hall sensors, ADC to connect with a potentiometer, current feed, voltage feedback, and FOC signals. Project is compatible with microchip PICDEM MCLV board, HEX firmware of MCLV board directly can work with this board. This board is mainly targeted to control brushless DC (BLDC) motors in hall sensor operations.

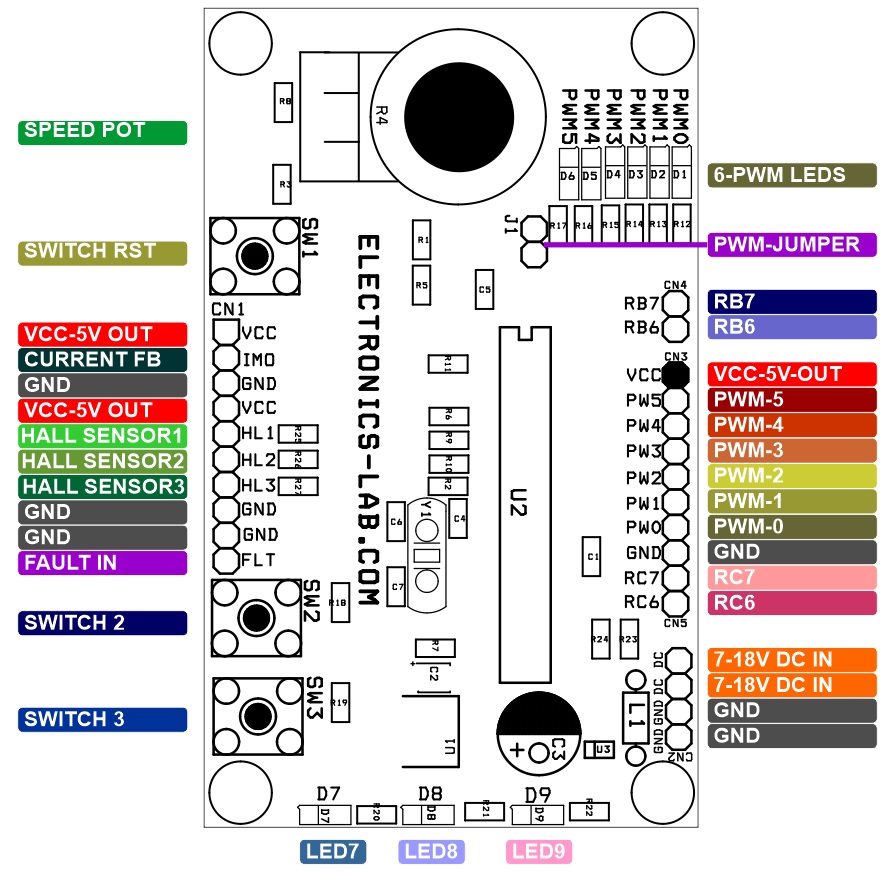

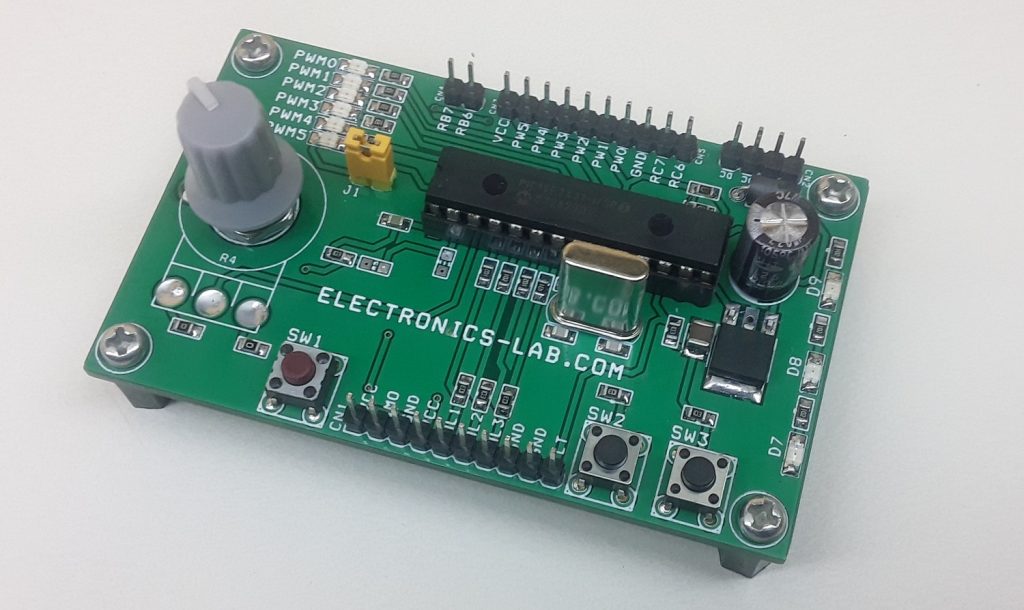

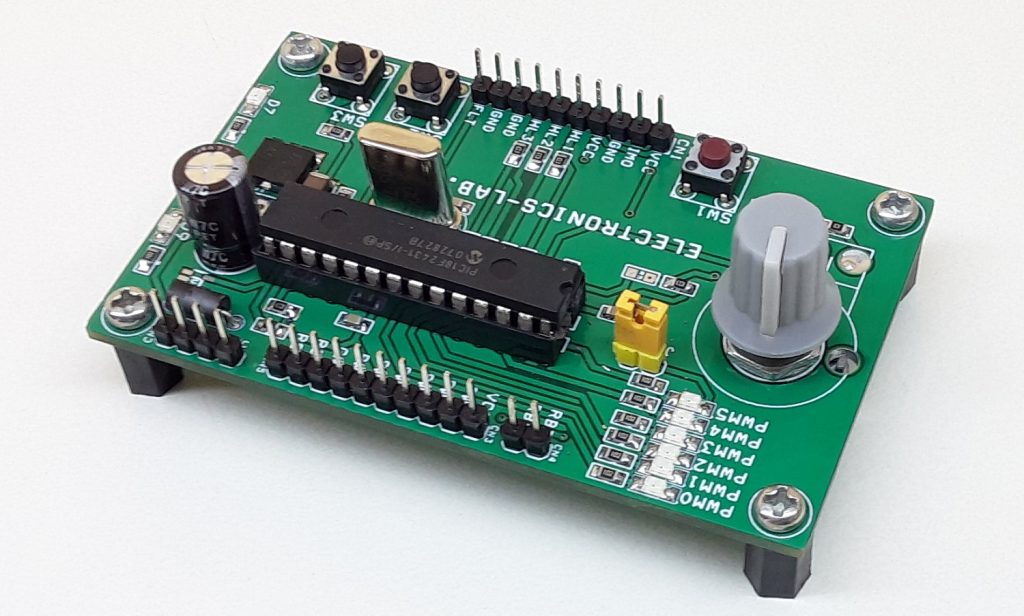

Board Connectors

Connector CN1 (Inputs and Outputs)

- Pin1>>VCC-5V DC Output,

- Pin2>> IMO-Current feedback

- Pin3>>GND

- Pin4>>VCC-5V DC Out

- Pin5>> Hall Sensor 1 (Input)

- Pin6>> Hall Sensor 2 (Input)

- Pin7>> Hall Sensor 3 (Input)

- Pin8>> GND

- Pin9>>GND

- Pin10>>Fault Input (From IPM Trip)

Connector CN2 (DC Supply Input)

- Pin1 >> 7-18V DC

- Pin1>> 7-18V DC

- Pin3>> GND

- Pin4>> GND

Connector CN3 (PWM Outputs for Hybrid IC, IPM Module)

- Pin1>> VCC

- Pin2>> PWM5

- Pin3>> PWM4

- Pin4>> PWM3

- Pin5>> PWM2

- Pin6>> PWM1

- Pin7>> PWM0

- Pin8>> GND

Connector CN4

- PIN1 >> RB7

- Pin2>> RB6

Connector CN5

- Pin1>>RC7 >> RX RS232

- Pin2>>RC6>> TX RS232

Other Components

- SW1>>Reset Switch

- SW2>>Run/Stop

- SW3>>Direction Change

- Potentiometer R4 >> Speed Control

- Jumper J1 >> Disables PWM LEDs

LED

- 6 PWM LEDs =D1, D2, D3, D4, D5, D6

- D7>> Switch Function S2 and S3

- D8>> Switch Function S2 and S3

- D9>> Over Current Fault – If this LED blinks

Operations

- Connect the board with IPM, Hybrid IC Board 6PWM, ITRIP and Current Sense

- Keep the potentiometer “REF” turned counter clockwise.

- Connect the Power Supply 7 to 18V

- Press and release switch S2 once.

- Turn the potentiometer “REF” clockwise, the motor should rotate.

- Each press of S2 toggles the control between Run and Stop conditions.

- To change the direction of rotation, press S3.

- If the motor stops and LED D1 blinks, it indicates that there was an overcurrent

- Reduce the speed “REF” and press either S2 or S3 to clear the Fault and resume operation

Specifications

- PCB Dimensions: 82.55 x 49.85 mm

Schematic

Parts List

| NO. | QNTY | REF. | DESC. | MANUFACTURER | SUPPLIER | SUPPLIER PART NO |

|---|---|---|---|---|---|---|

| 1 | 1 | CN1 | 10 PIN MALE HEADER PITCH 2.54MM | WURTH | DIGIKEY | 732-2670-ND |

| 2 | 1 | CN2 | 2 PIN MALE HEADER PITCH 2.54MM | WURTH | DIGIKEY | 732-5315-ND |

| 3 | 1 | CN3 | 8 PIN MALE HEADER PITCH 2.54MM | WURTH | DIGIKEY | 732-5321-ND |

| 4 | 2 | CN4,CN5 | 2 PIN MALE HEADER PITCH 2.54MM | WURTH | DIGIKEY | 732-5315-ND |

| 5 | 3 | C1,C4,C5 | 0.1uF/50V SMD SIZE 0805 | MUARATA/YAGEO | DIGIKEY | |

| 6 | 1 | C2 | 10uF/10V SMD SIZE 1206 OR 1210 | MUARATA/YAGEO | DIGIKEY | |

| 7 | 1 | C3 | 220uF/25V ELECTROLYTIC | NICHICON | DIGIKEY | 493-15236-3-ND |

| 8 | 2 | C6,C7 | 33PF/50V SMD SIZE 0805 | MUARATA/YAGEO | DIGIKEY | |

| 9 | 9 | D1,D2,D3,D4, | LED SMD RED COLOR SIZE 1206 | EVERLIGHT | DIGIKEY | 1080-1417-2-ND |

| D5,D6,D7,D8,D9 | LED SMD RED COLOR SIZE 1206 | EVERLIGHT | DIGIKEY | 1080-1417-2-ND | ||

| 10 | 1 | J1 | JUMPER AND SHUNT | SHULINS | DIGIKEY | S9001-ND |

| 11 | 1 | L1 | FERITE/THT | KEMET | MOUSER | 80-B-01-A |

| 12 | 9 | R1,R7,R18,R19, | 10K 5% SMD SIZE 0805 | MUARATA/YAGEO | ||

| R23,R24,R25,R26 | 10K 5% SMD SIZE 0805 | MUARATA/YAGEO | ||||

| R27 | 10K 5% SMD SIZE 0805 | MUARATA/YAGEO | ||||

| 13 | 1 | R2 | 470E 5% SMD SIZE 0805 | MUARATA/YAGEO | ||

| 14 | 1 | R3 | 0E SMD SIZE 0805 | MUARATA/YAGEO | ||

| 15 | 2 | R5,R11 | DNP | |||

| 16 | 12 | R6,R9,R10,R12,R13 | 1K 5% SMD SIZE 0805 | MUARATA/YAGEO | ||

| R14,R15,R16,R17,R20 | 1K 5% SMD SIZE 0805 | MUARATA/YAGEO | ||||

| R21,R22 | 1K 5% SMD SIZE 0805 | MUARATA/YAGEO | ||||

| 17 | 1 | R8 | 100E 5% SMD SIZE 0805 | MUARATA/YAGEO | ||

| 18 | 1 | SW1 | TACT SWITCH | C&K | DIGIKEY | CKN9085CT-ND |

| 19 | 1 | SW2 | TACT SWITCH | C&K | DIGIKEY | CKN9085CT-ND |

| 20 | 1 | SW3 | TACT SWITCH | C&K | DIGIKEY | CKN9085CT-ND |

| 21 | 1 | U1 | LM7805-DAPK D | ON SEMI | DIGIKEY | MC78M05CDTGOS-ND |

| 22 | 1 | U2 | PIC18F2431 | MICROCHIP | MOUSER | 579-PIC18F2431-I/SP |

| 23 | 1 | U3 | DNP | |||

| 24 | 1 | Y1 | 5MHZ | ECS INC | DIGIKEY | XC1738-ND |

| 25 | 1 | J1 | 2 PIN MALE HEADER PITCH 2.54MM | WURTH | DIGIKEY | 732-5315-ND |

| 26 | 1 | SOCKET | 28 PIN DIP IC SOCKET | ON SHORE TECH | DIGIKEY | ED3050-5-ND |

| 27 | 1 | R4 | POTENTIOMETER | TTE | DIGIKEY | 987-1715-ND |

Connections

Block Diagram

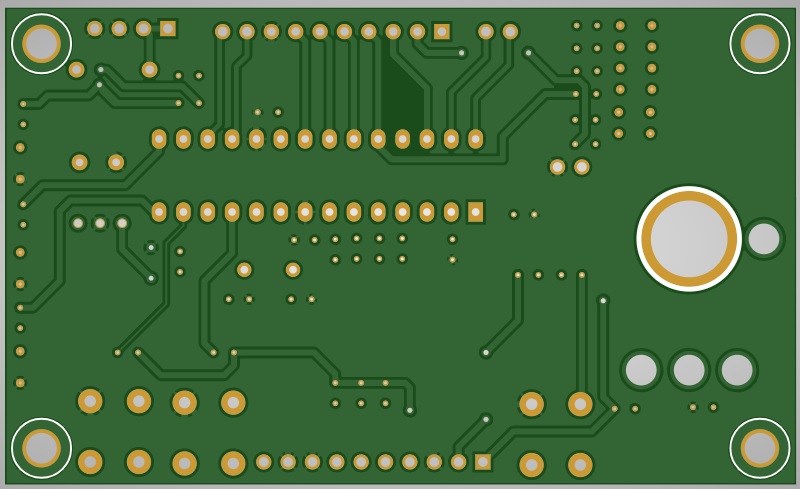

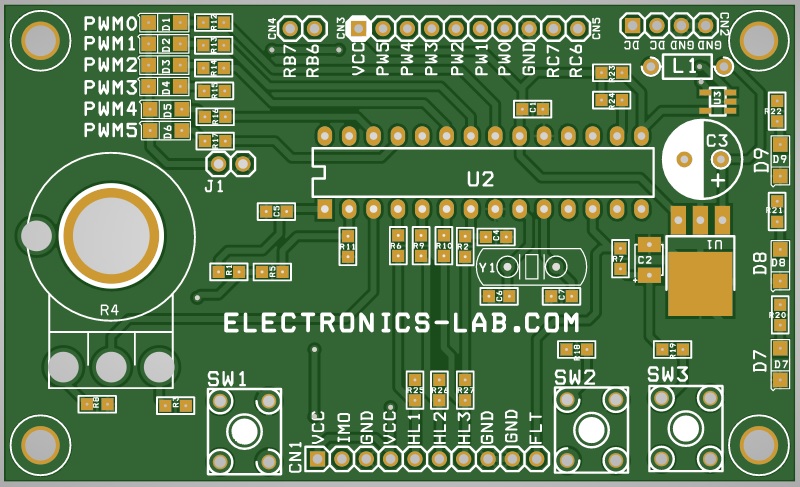

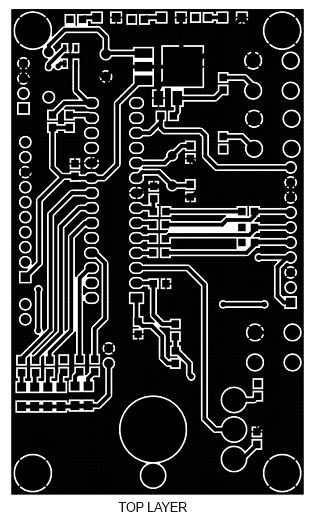

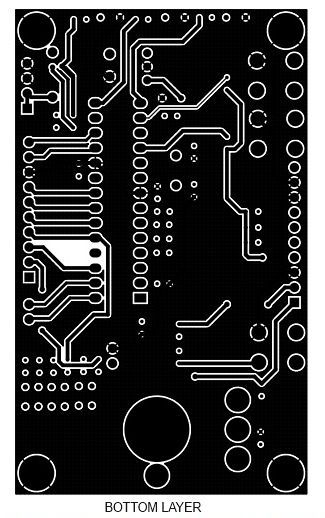

Gerber View

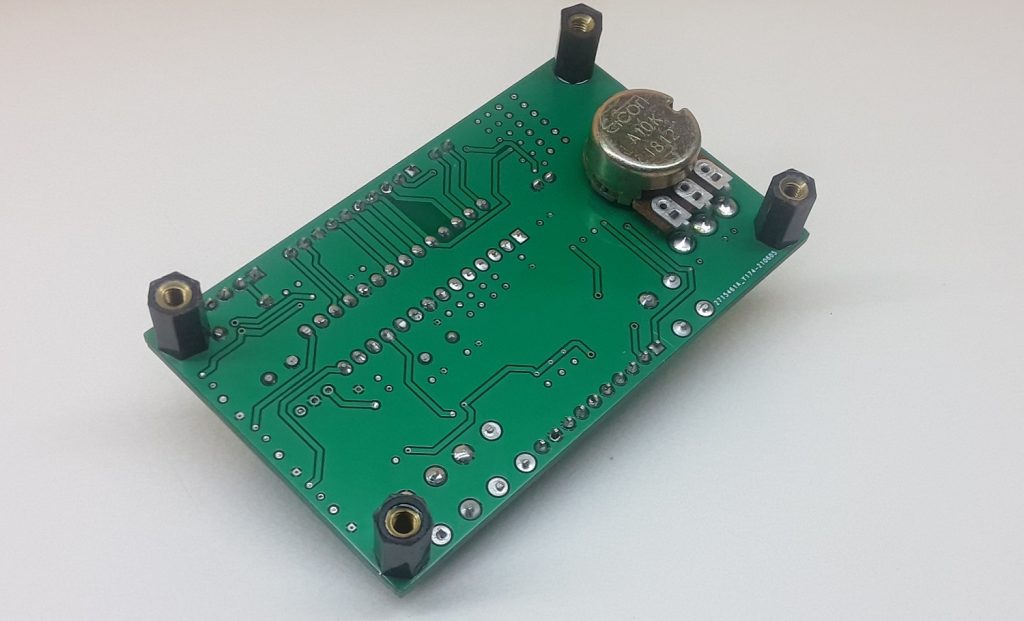

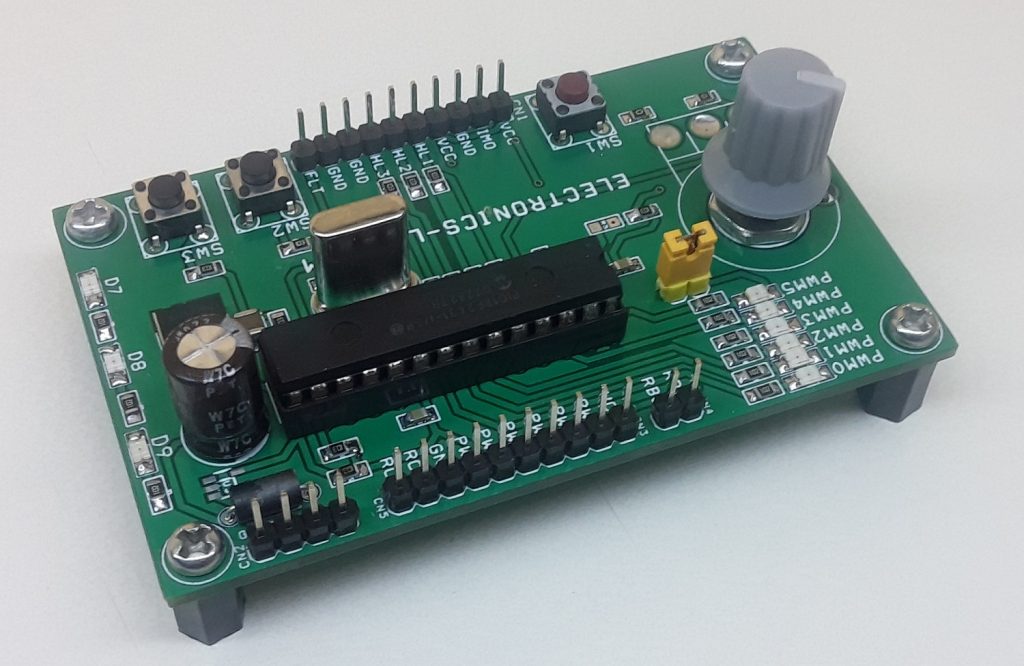

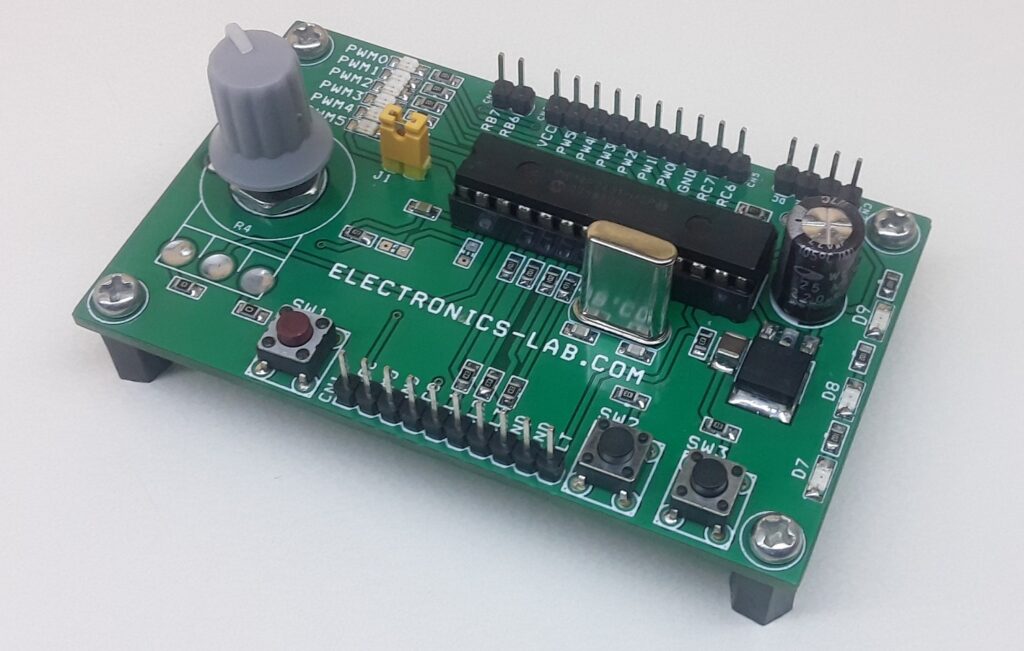

Photos

Video

Does this work with motors that have no Hall Sensors?